Tshuaj Tiv Thaiv Vial Filling Stoppering Capping Tshuab

Lub vial filling ntau lawm kab yog tsim los ntawm ultrasonic lub raj mis ntxhua khaub ncaws, tshuab ziab khaub ncaws, filling stoppering tshuab, thiab capping tshuab.Nws tuaj yeem ua kom tiav cov dej txau, ntxuav ultrasonic, yaug ntawm sab hauv thiab sab nrauv phab ntsa ntawm lub raj mis, preheating, ziab thiab sterilization, cua sov qhov chaw tshem tawm, txias, lub raj mis unscrambling, (nitrogen pre-filling), filling, (nitrogen post-filling), stopper unscrambling, stopper nias, cap unscrambling, capping thiab lwm yam complex functions, realizing tsis siv neeg ntau lawm ntawm tag nrho cov txheej txheem.Txhua lub tshuab tuaj yeem siv sib cais, lossis hauv kab sib txuas.Tag nrho cov kab no tsuas yog siv rau kev sau cov vial kua tshuaj thiab cov tshuaj khov-qhuav hmoov tshuaj hauv cov chaw tsim tshuaj, nws tseem tuaj yeem siv rau kev tsim cov tshuaj tua kab mob, bio-pharmaceuticals, tshuaj tshuaj, tshuaj ntshav thiab lwm yam.

| Qauv | SHPD 4 | SHPD 6 | SHPD 8 | SHP 10 | SHP 12 | NP20 | PAB 24 |

| Siv tau specifications | 2 ~ 30ml vial fwj | ||||||

| Sau taub hau | 4 | 6 | 8 | 10 | 12 | 20 | 24 |

| Muaj peev xwm ntau lawm | 50-100bts/min | 80-150bts / min | 100-200bts / min | 150-300bts / min | 200-400bts / min | 250-500bts / min | 300-600bts / min |

| Nres kev tsim nyog tus nqi | > = 99% | ||||||

| Laminar huab cua huv | 100 qib | ||||||

| Nqus twj tso kua mis ceev | 10 m3/h | 30 m3/h | 50 m3/h | 60 m3/h | 60 m3/h | 100 m3/h | 120 m3/h |

| Kev siv fais fab | 5 kws | ||||||

| Fais fab mov | 220V / 380V 50Hz | ||||||

1.Nws tuaj yeem nruab nrog kev tiv thaiv npog thiab kev kuaj xyuas-poob kev teeb tsa raws li tus neeg siv khoom xav tau.

2.Nws muaj qhov zoo ntawm qib siab automation degree, siab-tus nqi ntawm cov khoom tiav, zoo adaptability thiab stability uas yog nrov ntawm cov neeg siv.

3. Nws txais PLC qhov kev pab cuam los tswj, nruab nrog kov npo txiv neej-tshuab interface system, nws yooj yim thiab yooj yim rau kev khiav lag luam.

4.Lub tshuab filling yog tsim raws li GMP cov cai, uas yog ua los ntawm stainless hlau raws li thoob ntiaj teb ntawm SUS316L, SUS304.

Lub vial qhuav tuaj (sterilized thiab siliconised) yog pub los ntawm lub unscrambler thiab haum rau kev txav delrin slat conveyor siv ntawm qhov yuav tsum tau ceev ntawm qhov tseeb qhov chaw hauv qab no filling unit.Lub tshuab filling muaj xws li Filling Head, Syringes & Nozzles uas yog siv rau cov kua filling.Cov koob txhaj tshuaj yog ua los ntawm SS 316 kev tsim kho thiab ob qho tib si, iav thiab SS syringes tuaj yeem siv tau.Lub Hnub Qub Log yog muab los tuav lub vial thaum lub sijhawm ua haujlwm puv.Ib tug sensor yog muab.

1) Qhov no yog ntim cov kav dej, nws yog cov kav dej zoo tuaj.Nws muaj cov li qub ntawm cov yeeb nkab, nws yuav nqus cov kua dej rov qab tom qab ib zaug txhaws.Yog li filling nozzles yuav tsis to.

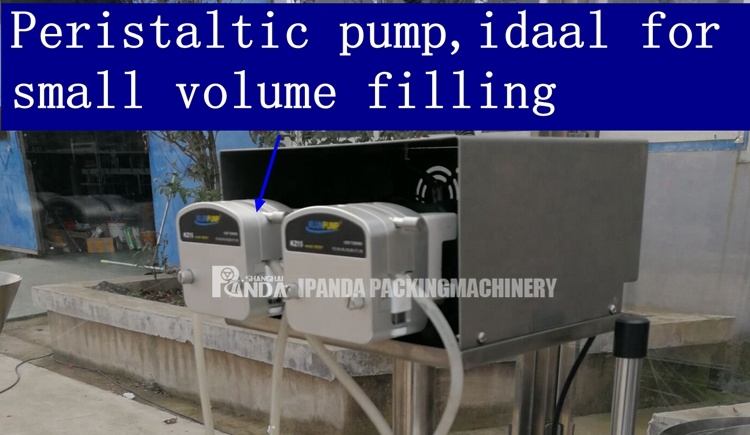

2) Cov txheej txheem ntau ntawm peb lub twj tso kua mis peristaltic ntxiv txhim kho kev ruaj ntseg thiab tsis cuam tshuam ntawm kev sau thiab ua rau cov kua filling ruaj khov thiab tsis yooj yim rau blister.Nws yog tshwj xeeb tshaj yog haum rau sau cov kua nrog siab yuav tsum tau.

3) Qhov no yog txhuas Cap sealing taub hau.Nws muaj peb lub sealing roller.Nws yuav sealing Cap los ntawm plaub sab, yog li lub sealed Cap yog nruj heev thiab zoo nkauj.Nws yuav tsis puas Cap los yog leakage Cap.

1.Peb tuaj yeem muab OEC / ODM tsim.

2.Peb muab 1 xyoo lav thiab khoom seem dawb (tsis yog neeg tsim tawg), peb tseem yuav npaj cov khoom seem xa tuaj.

ua ke nrog cov tshuab.

3.Our tshuab yog tsim los ntawm cov qauv yooj yim, kom yooj yim rau kev khiav lag luam thiab debugging.

4.Engineers muaj rau kev pab cuam machinerytxawv teb chaws