Tsis siv neeg roj teeb syringe test tube labeling tshuab

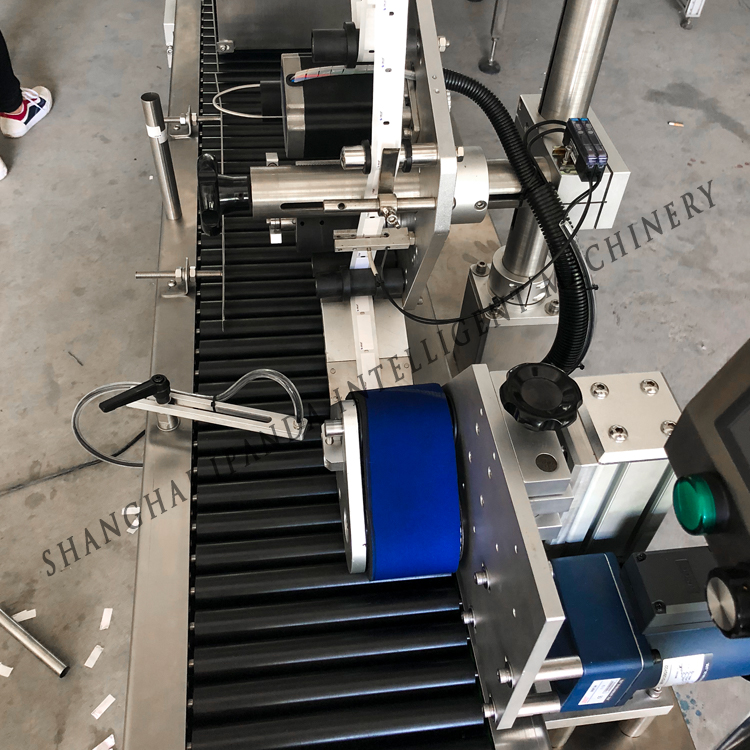

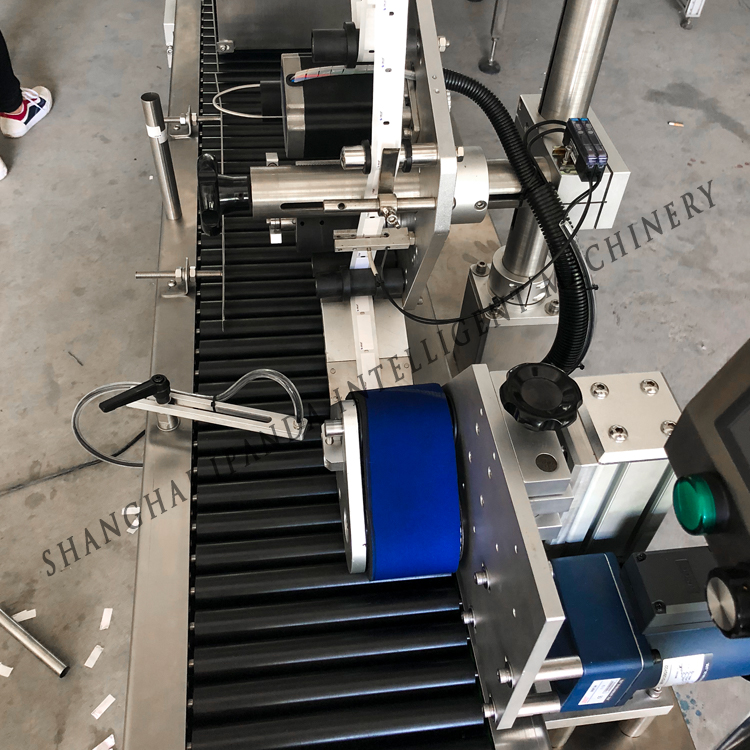

Tsim nyog rau lub voj voog lossis ib lub voj voog ntawm cov khoom cylindrical nrog cov kab me me uas tsis yooj yim rau sawv ntsug. Kab rov tav hloov thiab kab rov tav daim ntawv lo yog siv los ua kom muaj kev ruaj ntseg thiab cov ntawv sau ua haujlwm siab heev.Siv dav hauv tshuaj pleev ib ce, zaub mov, tshuaj, tshuaj, ntawv sau, electronics, hardware, khoom ua si, plastics thiab lwm yam lag luam.Xws li: mem pleev di ncauj, lub qhov ncauj lub raj mis, tshuaj me me lub raj mis, ampoule, syringe lub raj mis, xeem raj, roj teeb, ntshav, cwj mem, thiab lwm yam.

| Yield peev (lub raj mis / min) | 40-60 fwj / min |

| Txheem daim ntawv ceev (m / min) | ≤ 50 |

| Cov khoom tsim nyog | Hloov cov raj me me, cwj mem, lossis lwm yam chais |

| Daim ntawv lo raug | ± 0.5-1mm yuam kev |

| Daim ntawv lo specification | Glassine ntawv, pob tshab los yog opaque |

| Qhov Loj (mm) | 2000 (L) × 850 (W) × 1280 (H) (mm) |

| Daim ntawv yob (hauv) (mm) | 76mm ua |

| Daim ntawv yob (sab nraud) (mm) | £ 300 mm |

| Qhov hnyav (kg) | 200 kg |

| Lub zog (w) | 2 KW |

| Qhov hluav taws xob | 220V / 380V, 50 / 60HZ, ib zaug / peb theem |

| txheeb ze kub | 0 ~ 50 ºC |

1. Muaj feem xyuam, tshwj xeeb tshaj yog rau cov raj me me, lub raj mis los ua cov ntawv lo.

2. Lub voj voog dov labeling, dav siv hauv kev lag luam, khoom noj khoom haus, tshuaj pleev ib ce thiab lwm yam lag luam.

3. High precision ntawm labeling, acuities ntawm daim ntawv lo lub taub hau mus rau tus Tsov tus tw txuas hauv zos cia li ncav cuag + / - 1 hli

4. Qhov ntse extrusion hom ntaus ntawv pub, tsuas yog yuav tsum tau muab cov khoom tso, nws tuaj yeem sau npe

5. Siv cov anodic oxidation ntawm aluminium alloy stents thiab siab heev lub computer dawb lub thawv, kev zoo nkauj yog dav.

6. Siv cov khoom siv hluav taws xob siab tshaj plaws, cov khoom siv, daim ntawv lo siab kom paub meej rhiab heev.

7. Ua haujlwm nrog lub raj mis tswj tshuab, kev ua haujlwm tau zoo tuaj.

8. Kev xaiv code luam ntawv tshuab luam tawm hnub lossis batch naj npawb automaticlly, txhim kho cov txheej txheem.

Daim ntawv lo txoj hauj lwm ntawm qhov siab tuaj yeem hloov kho.

Lub tshuab muaj ntau yam haujlwm xws li kev taw qhia, sib cais, sau npe, txuas, suav.

Txais yuav tshiab ntsug hopper tsis siv neeg splitting qauvsiv lub raj mis hloov tau yooj yim faib thev naus laus zis thiab hloov tau yooj yim txheej conveying tshuab, zoo tshem tawm lub raj mis los ntawm qhov yuam kev ntawm lub raj mis nws tus kheej thiab txhim kho kev ruaj ntseg;