-

Tsis Siv Neeg Electronic Cigarette Liquid Filling Capping Tshuab

Txheej txheem cej luam

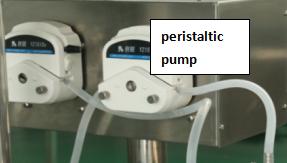

Lub tshuab filling thiab capping tsis siv neeg yog cov cuab yeej tsim los rau cov kua fwj.Nws siv Peristaltic twj tso kua mis filling, positioning type cap feeder, capping, thiab magnetic moment capping.Siv PLC, kov npo tswj, imported photoelectric nrhiav tau, siab precision, dav siv nyob rau hauv kws, zaub mov, tshuaj, khoom kho mob, tshuaj tua kab thiab lwm yam lag luam.Ua raws li kev ua raws li GMP tshiab.

Nta:

1. Lub tshuab no siv lub hau ntswj ntsia hlau tas li, nruab nrog cov khoom siv zawv zawg tsis siv neeg, txhawm rau tiv thaiv lub hau kev puas tsuaj;

2. Peristaltic twj tso kua mis filling, ntsuas precision, yooj yim manipulation;

3. Filling system muaj nuj nqi ntawm nqus rov qab, tsis txhob ua kua los ntawm;

4. Xim kov npo zaub, PLC tswj qhov system, tsis muaj lub raj mis filling, tsis ntxiv ntsaws, tsis muaj capping;

5. Ntxiv cov khoom siv ntsaws tuaj yeem xaiv cov pwm ruaj khov lossis lub tshuab nqus tsev pwm;

6. Tshuab yog tsim los ntawm 316 thiab 304 stainless hlau, yooj yim rau dismantle thiab huv si, tag nrho ua raws li GMP cov cai.

Thov saib daim vis dis aus no ntawm tsis siv neeg e-kua filling thiab capping tshuab

Peb kuj tuaj yeem muab qhov tsis siv neeg e-kua filling capping labeling tshuab kab

Cov txheej txheem ua haujlwm

Lub raj mis unscrambling (optional device)

Peristaltic twj tso kua mis filling (tsis muaj lub raj mis tsis filling)

Inner plug loading thiab nias los ntawm vibrating phaj (tsis muaj lub raj mis tsis thauj khoom)

Sab nraum lub hau loading los ntawm vibrating phaj (tsis muaj ntsaws tsis thauj khoom)

Sab nrauv cap capping auto

Tsis siv neeg labeling tshuab (optional device)

Ua kom tiav fwj sau turntable (optional device)

Yuav txuas nrog lub tshuab cartoning (optional device)

Nws yog tsim rau cov khoom ntawm cov kua xws li e-kua, qhov muag poob, ntsia thawv polish thiab lwm yam. Nws yog dav siv rau kev sau cov khoom hauv kev lag luam xws li zaub mov, tshuaj pleev ib ce, tshuaj, roj, roj, kev lag luam tshuaj txhua hnub, tshuaj ntxuav tes, tshuaj tua kab thiab tshuaj lom neeg kev lag luam. lwm.

Parameters:

Main parameter ntawm lub tshuab

Lub npe Lub tshuab filling capping Ntim ntim 5-250ml, tuaj yeem kho tau Net nyhav 550 KG Sau taub hau 1-4 lub taub hau, tuaj yeem kho tau Lub raj mis txoj kab uas hla Tau customized Filling ceev 1000-2000BPH, tuaj yeem kho Lub raj mis qhov siab Tau customized Qhov hluav taws xob 220V, 380V, 50/60GZ Filling raug ± 1ml Hwj chim 1.2 KW TSI Cov khoom siv lub raj mis iav, lub raj mis yas Ua hauj lwm siab 0.6-0.8MP Cov khoom ntim Qhov muag poob, e-kua, cbd roj Kev siv cua 700L ib h Txais SS304 filling nozzles thiab zaub mov qib Silicone raj.

Txais yuav Peristaltic twj tso kua mis:

Nws yog haum rau cov kua filling.Capping ib feem:

Muab lub puab ntsaws-muab lub hau-ntsia lub hau.Txais yuav magnetic torque screwing capping:

sealing caps nruj thiab tsis muaj mob rau lub kaus mom, capping nozzles yog customized raws li lub kaus mom

Tuam txhab profile

Peb tsom rau kev tsim ntau hom kev sau cov kab ntau lawm rau cov khoom sib txawv, xws li cov tshuaj ntsiav, kua, muab tshuaj, hmoov, aerosol, kua corrosive thiab lwm yam, uas tau siv dav hauv kev lag luam sib txawv, suav nrog zaub mov / dej haus / tshuaj pleev ib ce / petrochemicals thiab lwm yam. machines tag nrho customized raws li cov neeg siv khoom thiab thov.Lub tshuab ntim tshuab no yog tshiab hauv cov qauv, ruaj khov hauv kev ua haujlwm thiab yooj yim rau kev khiav lag luam. Zoo siab txais tos cov neeg siv khoom tshiab thiab qub tsab ntawv los sib tham txog kev txiav txim, kev tsim cov phooj ywg koom tes.Peb muaj cov neeg siv khoom hauv United States, Middle East, Southeast Asia, Russia thiab lwm yam thiab tau txais cov lus pom zoo los ntawm lawv nrog cov khoom zoo thiab cov kev pabcuam zoo.

Kev pab cuam tom qab muag:

Peb lav qhov zoo ntawm cov khoom tseem ceeb hauv 12 lub hlis.Yog hais tias cov khoom tseem ceeb mus tsis ncaj ncees lawm yam tsis muaj khoom tsim nyob rau hauv ib xyoos, peb yuav pub dawb rau lawv los yog khaws cia rau koj.Tom qab ib xyoos, yog tias koj xav tau hloov qhov chaw, peb yuav ua siab zoo muab tus nqi zoo tshaj plaws rau koj lossis tswj nws hauv koj qhov chaw.Thaum twg koj muaj lus nug txog kev siv nws, peb yuav dawb do ua peb qhov zoo tshaj plaws los txhawb koj.

Kev lav zoo:

Tus neeg tsim khoom yuav tsum tau lees tias cov khoom yog tsim los ntawm Tuam Tshoj cov ntaub ntawv zoo tshaj plaws, nrog rau kev ua haujlwm hauv chav ua haujlwm thawj zaug, cov khoom tshiab, tsis siv thiab sib haum nrog txhua yam ntawm qhov zoo, qhov tshwj xeeb thiab kev ua tau zoo raws li tau teev tseg hauv Daim Ntawv Cog Lus no.Lub sijhawm lav zoo yog nyob rau hauv 12 lub hlis txij li hnub B / L.Lub Chaw Tsim Tshuaj yuav kho cov tshuab cog lus pub dawb thaum lub sijhawm lav zoo.Yog tias qhov kev tawg tuaj yeem yog vim kev siv tsis raug lossis lwm yam laj thawj los ntawm Tus Neeg Yuav Khoom, Lub Chaw Tsim Khoom yuav sau cov nqi kho qhov chaw.

Installation thiab Debugging:

Tus neeg muag khoom yuav xa nws cov engineers los qhia kev teeb tsa thiab kev debugging.Tus nqi yuav dais ntawm tus neeg yuav khoom sab (piv txwv li daim pib davhlau, nqi kev pab hauv lub tebchaws yuav khoom).Tus neeg yuav khoom yuav tsum muab nws qhov chaw pab rau lub installation thiab debuggingFAQ

Q1: Koj lub tuam txhab cov khoom tseem ceeb yog dab tsi?

Palletizer, Conveyors, Filling Ntau Lawm Kab, Sealing Machine, Cap ping Machine, Packing Machine, thiab Labeling Machine.

Q2: Hnub xa khoom ntawm koj cov khoom yog dab tsi?

Hnub xa khoom yog 30 hnub ua haujlwm feem ntau ntawm cov tshuab.

Q3: Lub sijhawm them nyiaj yog dab tsi?Tso nyiaj 30% ua ntej thiab 70% ua ntej xa khoom xa tuaj.

Q5: Koj nyob qhov twg?Nws puas yooj yim tuaj xyuas koj?Peb nyob hauv Shanghai.Kev khiav tsheb yooj yim heev.

Q6: Koj tuaj yeem lav qhov zoo li cas?

1.Peb tau ua tiav cov txheej txheem ua haujlwm thiab cov txheej txheem thiab peb ua raws li lawv nruj heev.

2.Peb cov neeg ua haujlwm sib txawv yog lub luag haujlwm rau cov txheej txheem ua haujlwm sib txawv, lawv txoj haujlwm tau lees paub, thiab yuav ua haujlwm txhua lub sijhawm, yog li kev paub dhau los.

3. Cov khoom siv hluav taws xob pneumatic yog los ntawm lub ntiaj teb nto moo tuam txhab, xws li lub teb chaws Yelemees ^ Siemens, Japanese Panasonic thiab lwm yam.

4. Peb yuav ua qhov kev sim nruj heev tom qab lub tshuab ua tiav.

5.0ur tshuab tau ntawv pov thawj los ntawm SGS, ISO.

Q7: Koj puas tuaj yeem tsim lub tshuab raws li peb xav tau?Yog lawm.Peb tsis tsuas yog tuaj yeem kho lub tshuab raws li koj qhov kev kos duab techni cal, tab sis kuj tuaj yeem ua nws lub tshuab tshiab raws li koj xav tau.

Q8: Koj puas tuaj yeem muab kev pab cuam txawv teb chaws?

Yog lawm.Peb tuaj yeem xa engineer rau koj lub tuam txhab los teeb lub tshuab thiab cob qhia koj.

Lus Cim: Nyob rau hauv kev saib ntawm peb cov khoom qauv sib txawv, dav siv nyob rau hauv ntau industries, nyob rau hauv thiaj li yuav txhim kho kev sib txuas lus efficiency .so pls nco ntsoov qhov loj qhov hnyav thiab lub npe ntawm cov khoom kuaj ua ntej xa peb nug .yog li peb tuaj yeem xaiv qhov tsim nyog rau koj, xa nthuav dav thiab hais lus rau koj tus email .ua tsaug rau koj nkag siab.

-

Tsis Siv Neeg Eliquid E-Cigarette Roj Filling Plugging Capping Tshuab

Txheej txheem cej luam

Lub tshuab no yog ib qho ntawm cov tsoos filling stoppering thiab capping cov cuab yeej, kev tsim kho siab heev, tsim nyog qauv, tuaj yeem ua tiav cov filling, stoppering thiab capping txheej txheem, yog tsim rau qhov muag poob, eliquid, thiab lwm yam vial fwj xws li, tsis muaj lub raj mis filling, tsis muaj lub raj mis tsis nres (plug), thiab lwm yam haujlwm.Yuav siv tau stand-alone, thiab kuj yuav siv tau rau filling kab.Lub tshuab no ua tiav raws li GMP cov cai tshiab.

Nta:

1. Lub tshuab no siv lub hau ntswj ntsia hlau tas li, nruab nrog cov khoom siv zawv zawg tsis siv neeg, txhawm rau tiv thaiv lub hau kev puas tsuaj;

2. Peristaltic twj tso kua mis filling, ntsuas precision, yooj yim manipulation;

3. Filling system muaj nuj nqi ntawm nqus rov qab, tsis txhob ua kua los ntawm;

4. Xim kov npo zaub, PLC tswj qhov system, tsis muaj lub raj mis filling, tsis ntxiv ntsaws, tsis muaj capping;

5. Ntxiv cov khoom siv ntsaws tuaj yeem xaiv cov pwm ruaj khov lossis lub tshuab nqus tsev pwm;

6. Tshuab yog tsim los ntawm 316 thiab 304 stainless hlau, yooj yim rau dismantle thiab huv si, tag nrho ua raws li GMP cov cai.

Thov saib daim vis dis aus no ntawm tsis siv neeg e-kua filling thiab capping tshuab

Peb kuj tuaj yeem muab qhov tsis siv neeg e-kua filling capping labeling tshuab kab

Cov txheej txheem ua haujlwm

Lub raj mis unscrambling (optional device)

Peristaltic twj tso kua mis filling (tsis muaj lub raj mis tsis filling)

Inner plug loading thiab nias los ntawm vibrating phaj (tsis muaj lub raj mis tsis thauj khoom)

Sab nraum lub hau loading los ntawm vibrating phaj (tsis muaj ntsaws tsis thauj khoom)

Sab nrauv cap capping auto

Tsis siv neeg labeling tshuab (optional device)

Ua kom tiav fwj sau turntable (optional device)

Yuav txuas nrog lub tshuab cartoning (optional device)

Nws yog tsim rau cov khoom ntawm cov kua xws li e-kua, qhov muag poob, ntsia thawv polish thiab lwm yam. Nws yog dav siv rau kev sau cov khoom hauv kev lag luam xws li zaub mov, tshuaj pleev ib ce, tshuaj, roj, roj, kev lag luam tshuaj txhua hnub, tshuaj ntxuav tes, tshuaj tua kab thiab tshuaj lom neeg kev lag luam. lwm.

Parameters:

Ntim ntim 2-30ml customize Tso zis 30-50 BPM Filling Precision ≤ ± 1% Fais fab mov 380V / 50Hz Capping Rate ≥99% Tus nqi nres ≥99% Huab cua 1.3 m3 / h 0.4-0.8 Mpa Hwj chim 2.0 kwm Qhov hnyav 5 50kg Dimension 1800 * 1000 * 1500 hli Txais SS304 filling nozzles thiab zaub mov qib Silicone raj.

Txais yuav Peristaltic twj tso kua mis:

Nws yog haum rau cov kua filling.Capping ib feem:

Muab lub puab ntsaws-muab lub hau-ntsia lub hau.Txais yuav magnetic torque screwing capping:

sealing caps nruj thiab tsis muaj mob rau lub kaus mom, capping nozzles yog customized raws li lub kaus mom

Tuam txhab profile

Peb tsom rau kev tsim ntau hom kev sau cov kab ntau lawm rau cov khoom sib txawv, xws li cov tshuaj ntsiav, kua, muab tshuaj, hmoov, aerosol, kua corrosive thiab lwm yam, uas tau siv dav hauv kev lag luam sib txawv, suav nrog zaub mov / dej haus / tshuaj pleev ib ce / petrochemicals thiab lwm yam. machines tag nrho customized raws li cov neeg siv khoom thiab thov.Lub tshuab ntim tshuab no yog tshiab hauv cov qauv, ruaj khov hauv kev ua haujlwm thiab yooj yim rau kev khiav lag luam. Zoo siab txais tos cov neeg siv khoom tshiab thiab qub tsab ntawv los sib tham txog kev txiav txim, kev tsim cov phooj ywg koom tes.Peb muaj cov neeg siv khoom hauv United States, Middle East, Southeast Asia, Russia thiab lwm yam thiab tau txais cov lus pom zoo los ntawm lawv nrog cov khoom zoo thiab cov kev pabcuam zoo.

Kev pab cuam tom qab muag:

Peb lav qhov zoo ntawm cov khoom tseem ceeb hauv 12 lub hlis.Yog hais tias cov khoom tseem ceeb mus tsis ncaj ncees lawm yam tsis muaj khoom tsim nyob rau hauv ib xyoos, peb yuav pub dawb rau lawv los yog khaws cia rau koj.Tom qab ib xyoos, yog tias koj xav tau hloov qhov chaw, peb yuav ua siab zoo muab tus nqi zoo tshaj plaws rau koj lossis tswj nws hauv koj qhov chaw.Thaum twg koj muaj lus nug txog kev siv nws, peb yuav dawb do ua peb qhov zoo tshaj plaws los txhawb koj.

Kev lav zoo:

Tus neeg tsim khoom yuav tsum tau lees tias cov khoom yog tsim los ntawm Tuam Tshoj cov ntaub ntawv zoo tshaj plaws, nrog rau kev ua haujlwm hauv chav ua haujlwm thawj zaug, cov khoom tshiab, tsis siv thiab sib haum nrog txhua yam ntawm qhov zoo, qhov tshwj xeeb thiab kev ua tau zoo raws li tau teev tseg hauv Daim Ntawv Cog Lus no.Lub sijhawm lav zoo yog nyob rau hauv 12 lub hlis txij li hnub B / L.Lub Chaw Tsim Tshuaj yuav kho cov tshuab cog lus pub dawb thaum lub sijhawm lav zoo.Yog tias qhov kev tawg tuaj yeem yog vim kev siv tsis raug lossis lwm yam laj thawj los ntawm Tus Neeg Yuav Khoom, Lub Chaw Tsim Khoom yuav sau cov nqi kho qhov chaw.

Installation thiab Debugging:

Tus neeg muag khoom yuav xa nws cov engineers los qhia kev teeb tsa thiab kev debugging.Tus nqi yuav dais ntawm tus neeg yuav khoom sab (piv txwv li daim pib davhlau, nqi kev pab hauv lub tebchaws yuav khoom).Tus neeg yuav khoom yuav tsum muab nws qhov chaw pab rau lub installation thiab debuggingFAQ

Q1: Koj lub tuam txhab cov khoom tseem ceeb yog dab tsi?

Palletizer, Conveyors, Filling Ntau Lawm Kab, Sealing Machine, Cap ping Machine, Packing Machine, thiab Labeling Machine.

Q2: Hnub xa khoom ntawm koj cov khoom yog dab tsi?

Hnub xa khoom yog 30 hnub ua haujlwm feem ntau ntawm cov tshuab.

Q3: Lub sijhawm them nyiaj yog dab tsi?Tso nyiaj 30% ua ntej thiab 70% ua ntej xa khoom xa tuaj.

Q5: Koj nyob qhov twg?Nws puas yooj yim tuaj xyuas koj?Peb nyob hauv Shanghai.Kev khiav tsheb yooj yim heev.

Q6: Koj tuaj yeem lav qhov zoo li cas?

1.Peb tau ua tiav cov txheej txheem ua haujlwm thiab cov txheej txheem thiab peb ua raws li lawv nruj heev.

2.Peb cov neeg ua haujlwm sib txawv yog lub luag haujlwm rau cov txheej txheem ua haujlwm sib txawv, lawv txoj haujlwm tau lees paub, thiab yuav ua haujlwm txhua lub sijhawm, yog li kev paub dhau los.

3. Cov khoom siv hluav taws xob pneumatic yog los ntawm lub ntiaj teb nto moo tuam txhab, xws li lub teb chaws Yelemees ^ Siemens, Japanese Panasonic thiab lwm yam.

4. Peb yuav ua qhov kev sim nruj heev tom qab lub tshuab ua tiav.

5.0ur tshuab tau ntawv pov thawj los ntawm SGS, ISO.

Q7: Koj puas tuaj yeem tsim lub tshuab raws li peb xav tau?Yog lawm.Peb tsis tsuas yog tuaj yeem kho lub tshuab raws li koj qhov kev kos duab techni cal, tab sis kuj tuaj yeem ua nws lub tshuab tshiab raws li koj xav tau.

Q8: Koj puas tuaj yeem muab kev pab cuam txawv teb chaws?

Yog lawm.Peb tuaj yeem xa engineer rau koj lub tuam txhab los teeb lub tshuab thiab cob qhia koj.

Lus Cim: Nyob rau hauv kev saib ntawm peb cov khoom qauv sib txawv, dav siv nyob rau hauv ntau industries, nyob rau hauv thiaj li yuav txhim kho kev sib txuas lus efficiency .so pls nco ntsoov qhov loj qhov hnyav thiab lub npe ntawm cov khoom kuaj ua ntej xa peb nug .yog li peb tuaj yeem xaiv qhov tsim nyog rau koj, xa nthuav dav thiab hais lus rau koj tus email .ua tsaug rau koj nkag siab.

-

E-Liquid Filling Plugging & Capping Tshuab nrog GMP Standards

Txheej txheem cej luam:

Lub tshuab no tsuas yog muaj los sau Cov Roj, Qhov muag-poob, Tshuaj pleev ib ce roj, E-kua rau hauv ntau yam puag ncig thiab tiaj tus iav fwj nrog qhov ntau ntawm 10-50ml.High precision cam muab lub phaj tsis tu ncua rau txoj hauj lwm, cork thiab cap;ceev cam ua rau capping taub hau nce thiab nqis;tas li tig caj npab screws caps;piston ntsuas ntim ntim;thiab kov npo tswj txhua qhov kev ua.Tsis muaj lub raj mis filling thiab tsis muaj capping.Lub tshuab nyiam qhov tseeb ntawm txoj haujlwm siab, kev tsav tsheb ruaj khov, kev siv ntau npaum li cas, thiab kev ua haujlwm yooj yim thiab tseem tiv thaiv lub kaus mom lub raj mis.Servo lub cev muaj zog tswj peristaltic twj tso kua mis filling rau tsawg tham 50ml lub raj mis filling.

Yog tias cov neeg siv khoom xav tau 60ml lub raj mis lossis 120ml lub raj mis kuj tuaj yeem xaiv piston lub tog raj kheej filling.Filling ceev yuav nrawm dua,

Yog tias cov neeg siv khoom xav tau siab filling ceev.Tsis tas li ntawd tuaj yeem kho Doule chaw ua haujlwm (2 filling nozzle, 2 capping system, 2 plugging system) kom ntseeg tau tias kev kub ceevThov saib daim vis dis aus no ntawm tsis siv neeg e-kua filling thiab capping tshuab

Peb kuj tuaj yeem muab qhov tsis siv neeg e-kua filling capping labeling tshuab kab

Cov txheej txheem ua haujlwm

Lub raj mis unscrambling (optional device)

Peristaltic twj tso kua mis filling (tsis muaj lub raj mis tsis filling)

Inner plug loading thiab nias los ntawm vibrating phaj (tsis muaj lub raj mis tsis thauj khoom)

Sab nraum lub hau loading los ntawm vibrating phaj (tsis muaj ntsaws tsis thauj khoom)

Sab nrauv cap capping auto

Tsis siv neeg labeling tshuab (optional device)

Ua kom tiav fwj sau turntable (optional device)

Yuav txuas nrog lub tshuab cartoning (optional device)

Nta:

1. Lub tshuab no siv lub hau ntswj ntsia hlau tas li, nruab nrog cov khoom siv zawv zawg tsis siv neeg, txhawm rau tiv thaiv lub hau kev puas tsuaj;

2. Peristaltic twj tso kua mis filling, ntsuas precision, yooj yim manipulation;

3. Filling system muaj nuj nqi ntawm nqus rov qab, tsis txhob ua kua los ntawm;

4. Xim kov npo zaub, PLC tswj qhov system, tsis muaj lub raj mis filling, tsis ntxiv ntsaws, tsis muaj capping;

5. Ntxiv cov khoom siv ntsaws tuaj yeem xaiv cov pwm ruaj khov lossis lub tshuab nqus tsev pwm;

6. Tshuab yog tsim los ntawm 316 thiab 304 stainless hlau, yooj yim rau dismantle thiab huv si, tag nrho ua raws li GMP cov cai.

Nws yog tsim rau cov khoom ntawm cov kua xws li e-kua, qhov muag poob, ntsia thawv polish thiab lwm yam. Nws yog dav siv rau kev sau cov khoom hauv kev lag luam xws li zaub mov, tshuaj pleev ib ce, tshuaj, roj, roj, kev lag luam tshuaj txhua hnub, tshuaj ntxuav tes, tshuaj tua kab thiab tshuaj lom neeg kev lag luam. lwm.

Parameters:

Ntim ntim 2-30ml customize Tso zis 30-50 BPM Filling Precision ≤ ± 1% Fais fab mov 380V / 50Hz Capping Rate ≥99% Tus nqi nres ≥99% Huab cua 1.3 m3 / h 0.4-0.8 Mpa Hwj chim 2.0 kwm Qhov hnyav 5 50kg Dimension 1800 * 1000 * 1500 hli Txais SS304 filling nozzles thiab zaub mov qib Silicone raj.

Txais yuav Peristaltic twj tso kua mis:

Nws yog haum rau cov kua filling.Capping ib feem:

Muab lub puab ntsaws-muab lub hau-ntsia lub hau.Txais yuav magnetic torque screwing capping:

sealing caps nruj thiab tsis muaj mob rau lub kaus mom, capping nozzles yog customized raws li lub kaus mom

Tuam txhab profile

Peb tsom rau kev tsim ntau hom kev sau cov kab ntau lawm rau cov khoom sib txawv, xws li cov tshuaj ntsiav, kua, muab tshuaj, hmoov, aerosol, kua corrosive thiab lwm yam, uas tau siv dav hauv kev lag luam sib txawv, suav nrog zaub mov / dej haus / tshuaj pleev ib ce / petrochemicals thiab lwm yam. machines tag nrho customized raws li cov neeg siv khoom thiab thov.Lub tshuab ntim tshuab no yog tshiab hauv cov qauv, ruaj khov hauv kev ua haujlwm thiab yooj yim rau kev khiav lag luam. Zoo siab txais tos cov neeg siv khoom tshiab thiab qub tsab ntawv los sib tham txog kev txiav txim, kev tsim cov phooj ywg koom tes.Peb muaj cov neeg siv khoom hauv United States, Middle East, Southeast Asia, Russia thiab lwm yam thiab tau txais cov lus pom zoo los ntawm lawv nrog cov khoom zoo thiab cov kev pabcuam zoo.

Kev pab cuam tom qab muag:

Peb lav qhov zoo ntawm cov khoom tseem ceeb hauv 12 lub hlis.Yog hais tias cov khoom tseem ceeb mus tsis ncaj ncees lawm yam tsis muaj khoom tsim nyob rau hauv ib xyoos, peb yuav pub dawb rau lawv los yog khaws cia rau koj.Tom qab ib xyoos, yog tias koj xav tau hloov qhov chaw, peb yuav ua siab zoo muab tus nqi zoo tshaj plaws rau koj lossis tswj nws hauv koj qhov chaw.Thaum twg koj muaj lus nug txog kev siv nws, peb yuav dawb do ua peb qhov zoo tshaj plaws los txhawb koj.

Kev lav zoo:

Tus neeg tsim khoom yuav tsum tau lees tias cov khoom yog tsim los ntawm Tuam Tshoj cov ntaub ntawv zoo tshaj plaws, nrog rau kev ua haujlwm hauv chav ua haujlwm thawj zaug, cov khoom tshiab, tsis siv thiab sib haum nrog txhua yam ntawm qhov zoo, qhov tshwj xeeb thiab kev ua tau zoo raws li tau teev tseg hauv Daim Ntawv Cog Lus no.Lub sijhawm lav zoo yog nyob rau hauv 12 lub hlis txij li hnub B / L.Lub Chaw Tsim Tshuaj yuav kho cov tshuab cog lus pub dawb thaum lub sijhawm lav zoo.Yog tias qhov kev tawg tuaj yeem yog vim kev siv tsis raug lossis lwm yam laj thawj los ntawm Tus Neeg Yuav Khoom, Lub Chaw Tsim Khoom yuav sau cov nqi kho qhov chaw.

Installation thiab Debugging:

Tus neeg muag khoom yuav xa nws cov engineers los qhia kev teeb tsa thiab kev debugging.Tus nqi yuav dais ntawm tus neeg yuav khoom sab (piv txwv li daim pib davhlau, nqi kev pab hauv lub tebchaws yuav khoom).Tus neeg yuav khoom yuav tsum muab nws qhov chaw pab rau lub installation thiab debuggingFAQ

Q1: Koj lub tuam txhab cov khoom tseem ceeb yog dab tsi?

Palletizer, Conveyors, Filling Ntau Lawm Kab, Sealing Machine, Cap ping Machine, Packing Machine, thiab Labeling Machine.

Q2: Hnub xa khoom ntawm koj cov khoom yog dab tsi?

Hnub xa khoom yog 30 hnub ua haujlwm feem ntau ntawm cov tshuab.

Q3: Lub sijhawm them nyiaj yog dab tsi?Tso nyiaj 30% ua ntej thiab 70% ua ntej xa khoom xa tuaj.

Q5: Koj nyob qhov twg?Nws puas yooj yim tuaj xyuas koj?Peb nyob hauv Shanghai.Kev khiav tsheb yooj yim heev.

Q6: Koj tuaj yeem lav qhov zoo li cas?

1.Peb tau ua tiav cov txheej txheem ua haujlwm thiab cov txheej txheem thiab peb ua raws li lawv nruj heev.

2.Peb cov neeg ua haujlwm sib txawv yog lub luag haujlwm rau cov txheej txheem ua haujlwm sib txawv, lawv txoj haujlwm tau lees paub, thiab yuav ua haujlwm txhua lub sijhawm, yog li kev paub dhau los.

3. Cov khoom siv hluav taws xob pneumatic yog los ntawm lub ntiaj teb nto moo tuam txhab, xws li lub teb chaws Yelemees ^ Siemens, Japanese Panasonic thiab lwm yam.

4. Peb yuav ua qhov kev sim nruj heev tom qab lub tshuab ua tiav.

5.0ur tshuab tau ntawv pov thawj los ntawm SGS, ISO.

Q7: Koj puas tuaj yeem tsim lub tshuab raws li peb xav tau?Yog lawm.Peb tsis tsuas yog tuaj yeem kho lub tshuab raws li koj qhov kev kos duab techni cal, tab sis kuj tuaj yeem ua nws lub tshuab tshiab raws li koj xav tau.

Q8: Koj puas tuaj yeem muab kev pab cuam txawv teb chaws?

Yog lawm.Peb tuaj yeem xa engineer rau koj lub tuam txhab los teeb lub tshuab thiab cob qhia koj.

-

E-Liquid Filling Line Pib Cbd Roj Tincture Lub raj mis Filling Capping Labeling Tshuab

Lub tshuab filling thiab capping tsis siv neeg yog cov cuab yeej tsim los rau cov kua fwj.Nws siv Peristaltic twj tso kua mis filling, positioning type cap feeder, capping, thiab magnetic moment capping.Siv PLC, kov npo tswj, imported photoelectric nrhiav tau, siab precision, dav siv nyob rau hauv kws, zaub mov, tshuaj, khoom kho mob, tshuaj tua kab thiab lwm yam lag luam.Ua raws li kev ua raws li GMP tshiab.

-

Tsis Siv Neeg Monoblock Filling Stoppering Capping Labeling Tshuab rau E-kua

Txheej txheem cej luam:

E kua lub raj mis filling capping tshuab nrog luv nqi zoo tshaj plaws rau cov roj yam tseem ceeb thiab e-luam yeeb kua Feem ntau yog tsim rau tsis siv neeg filling, stoppering thiab ntsia hlau capping ntawm hluav taws xob luam yeeb kua, e-kua, qhov muag tee, ntsia thawv polish, qhov muag ntxoov ntxoo, roj yam tseem ceeb, nrog ntim ntim tsawg dua 50 ml.Thiab haum rau iav dropper lub raj mis filling thiab capping rau cov roj yam tseem ceeb tau txais.Kuj haum rau VG, PG kua filling thiab capping.

Thov saib daim vis dis aus no ntawm tsis siv neeg e-kua filling thiab capping tshuab

Kauj ruam ua haujlwm:

Tsis siv neeg pub rau lub raj mis-sau-tsis siv neeg pub rau lub hau / ntsaws-capping- tawm tso.Nta:

1. Lub tshuab filling thiab capping no yog ntau lub tshuab ua haujlwm monoblock nrog cov qauv tsim..

2. Lub tshuab no siv rau cov khoom noj khoom haus, khw muag tshuaj, tshuaj pleev ib ce, tshuaj thiab tshuaj tua kab.

4. Lub tshuab yog tswj los ntawm PLC thiab kov npo.

5. Nws siv Peristaltic twj tso kua mis filling system.

6. Yooj yim rau txhua yam capping taub hau, ntsia hlau, xovxwm, alu.Yob.

7. Nws yog cov cuab yeej zoo tshaj plaws rau kev muaj peev xwm tsawg.Nws tuaj yeem zawm lub kaus mom txiav.

8. Txhua qhov chaw uas kov cov khoom yog ua los ntawm cov hlau tsis zoo, thiab cov nplaim tau polished, tsis muaj kuab paug rau ib puag ncig.

Nws yog tsim rau cov khoom ntawm cov kua xws li e-kua, qhov muag poob, ntsia thawv polish thiab lwm yam. Nws yog dav siv rau kev sau cov khoom hauv kev lag luam xws li zaub mov, tshuaj pleev ib ce, tshuaj, roj, roj, kev lag luam tshuaj txhua hnub, tshuaj ntxuav tes, tshuaj tua kab thiab tshuaj lom neeg kev lag luam. lwm.

Parameters:

Ntim ntim 2-30ml customize Tso zis 30-50 BPM Filling Precision ≤ ± 1% Fais fab mov 380V / 50Hz Capping Rate ≥99% Tus nqi nres ≥99% Huab cua 1.3 m3 / h 0.4-0.8 Mpa Hwj chim 2.0 kwm Qhov hnyav 5 50kg Dimension 1800 * 1000 * 1500 hli Txais SS304 filling nozzles thiab zaub mov qib Silicone raj.

Txais yuav Peristaltic twj tso kua mis:

Nws yog haum rau cov kua filling.Capping ib feem:

Muab lub puab ntsaws-muab lub hau-ntsia lub hau.Txais yuav magnetic torque screwing capping:

sealing caps nruj thiab tsis muaj mob rau lub kaus mom, capping nozzles yog customized raws li lub kaus mom

Tuam txhab profile

Shanghai Ipanda Intelligent Machinery Co. ltd yog lub chaw tsim khoom ntawm txhua yam khoom ntim khoom.Peb muab tag nrho cov kab ntau lawm suav nrog lub raj mis noj tshuab, filling tshuab, capping tshuab, labeling tshuab, packing tshuab thiab auxiliary khoom rau peb cov neeg muas zaub.

Kev pab cuam tom qab muag:

Peb lav qhov zoo ntawm cov khoom tseem ceeb hauv 12 lub hlis.Yog hais tias cov khoom tseem ceeb mus tsis ncaj ncees lawm yam tsis muaj khoom tsim nyob rau hauv ib xyoos, peb yuav pub dawb rau lawv los yog khaws cia rau koj.Tom qab ib xyoos, yog tias koj xav tau hloov qhov chaw, peb yuav ua siab zoo muab tus nqi zoo tshaj plaws rau koj lossis tswj nws hauv koj qhov chaw.Thaum twg koj muaj lus nug txog kev siv nws, peb yuav dawb do ua peb qhov zoo tshaj plaws los txhawb koj.

Kev lav zoo:

Tus neeg tsim khoom yuav tsum tau lees tias cov khoom yog tsim los ntawm Tuam Tshoj cov ntaub ntawv zoo tshaj plaws, nrog rau kev ua haujlwm hauv chav ua haujlwm thawj zaug, cov khoom tshiab, tsis siv thiab sib haum nrog txhua yam ntawm qhov zoo, qhov tshwj xeeb thiab kev ua tau zoo raws li tau teev tseg hauv Daim Ntawv Cog Lus no.Lub sijhawm lav zoo yog nyob rau hauv 12 lub hlis txij li hnub B / L.Lub Chaw Tsim Tshuaj yuav kho cov tshuab cog lus pub dawb thaum lub sijhawm lav zoo.Yog tias qhov kev tawg tuaj yeem yog vim kev siv tsis raug lossis lwm yam laj thawj los ntawm Tus Neeg Yuav Khoom, Lub Chaw Tsim Khoom yuav sau cov nqi kho qhov chaw.

Installation thiab Debugging:

Tus neeg muag khoom yuav xa nws cov engineers los qhia kev teeb tsa thiab kev debugging.Tus nqi yuav dais ntawm tus neeg yuav khoom sab (piv txwv li daim pib davhlau, nqi kev pab hauv lub tebchaws yuav khoom).Tus neeg yuav khoom yuav tsum muab nws qhov chaw pab rau lub installation thiab debuggingFAQ

Q1: Koj lub tuam txhab cov khoom tseem ceeb yog dab tsi?

Palletizer, Conveyors, Filling Ntau Lawm Kab, Sealing Machine, Cap ping Machine, Packing Machine, thiab Labeling Machine.

Q2: Hnub xa khoom ntawm koj cov khoom yog dab tsi?

Hnub xa khoom yog 30 hnub ua haujlwm feem ntau ntawm cov tshuab.

Q3: Lub sijhawm them nyiaj yog dab tsi?Tso nyiaj 30% ua ntej thiab 70% ua ntej xa khoom xa tuaj.

Q5: Koj nyob qhov twg?Nws puas yooj yim tuaj xyuas koj?Peb nyob hauv Shanghai.Kev khiav tsheb yooj yim heev.

Q6: Koj tuaj yeem lav qhov zoo li cas?

1.Peb tau ua tiav cov txheej txheem ua haujlwm thiab cov txheej txheem thiab peb ua raws li lawv nruj heev.

2.Peb cov neeg ua haujlwm sib txawv yog lub luag haujlwm rau cov txheej txheem ua haujlwm sib txawv, lawv txoj haujlwm tau lees paub, thiab yuav ua haujlwm txhua lub sijhawm, yog li kev paub dhau los.

3. Cov khoom siv hluav taws xob pneumatic yog los ntawm lub ntiaj teb nto moo tuam txhab, xws li lub teb chaws Yelemees ^ Siemens, Japanese Panasonic thiab lwm yam.

4. Peb yuav ua qhov kev sim nruj heev tom qab lub tshuab ua tiav.

5.0ur tshuab tau ntawv pov thawj los ntawm SGS, ISO.

Q7: Koj puas tuaj yeem tsim lub tshuab raws li peb xav tau?Yog lawm.Peb tsis tsuas yog tuaj yeem kho lub tshuab raws li koj qhov kev kos duab techni cal, tab sis kuj tuaj yeem ua nws lub tshuab tshiab raws li koj xav tau.

Q8: Koj puas tuaj yeem muab kev pab cuam txawv teb chaws?

Yog lawm.Peb tuaj yeem xa engineer rau koj lub tuam txhab los teeb lub tshuab thiab cob qhia koj.

-

Tsis siv neeg lub raj mis me me qhov muag poob Filling Plugging Capping Tshuab Ntau Lawm Kab

Txheej txheem cej luam:

Qhov no lub qhov muag tee filling thiab capping tshuab yog peb cov khoom ib txwm muaj, thiab raws li cov neeg siv khoom xav tau, peb muaj qee qhov kev tsim kho tshiab rau lub tshuab no.Qhov chaw & tracing filling yog saws rau 1 / 2 / 4 nozzles filling & capping tshuab, thiab cov khoom tsim tau txaus siab rau cov neeg siv.Tus pass tus nqi yog siab.Thiab raws li cov neeg siv khoom xav tau, lub tshuab ntxhua khaub ncaws / ziab khaub ncaws sib txuas lossis tshuab tshuab tuaj yeem txuas nrog.

Kauj ruam ua haujlwm:

Tsis siv neeg pub rau lub raj mis-sau-tsis siv neeg pub rau lub hau / ntsaws-capping- tawm tso.

feature:

1.Adopt human-computer interface, PLC maub los, yooj yim rau kev khiav lag luam

2.Siv zaus converting tswj, yooj yim los kho cov filling ceev, tsis siv neeg suav

3. Tsis siv neeg nres, tsis muaj lub raj mis filling.

4.Round tig lub rooj rau positioning filling, ruaj khov thiab txhim khu kev qha.

5.High precision CAM indexing gage tswj.Nws yog tsim rau cov khoom ntawm cov kua xws li e-kua, qhov muag poob, ntsia thawv polish thiab lwm yam. Nws yog dav siv rau kev sau cov khoom hauv kev lag luam xws li zaub mov, tshuaj pleev ib ce, tshuaj, roj, roj, kev lag luam tshuaj txhua hnub, tshuaj ntxuav tes, tshuaj tua kab thiab tshuaj lom neeg kev lag luam. lwm.

Parameters:

Siv tau specifications 1ml-200mml lossis customized Muaj peev xwm ntau lawm 30-40 Lub raj mis / min lossis 60-80BPM Filling raug ≤ ± 1% Fais fab mov 220V / 50Hz Rotating (rolling) npog tus nqi ≥99% Hwj chim 2.0 kwm Tshuab nqa hnyav 6 50kg Qhov ntev 2440 * 1700 * 1800 hli Txais SS304 filling nozzles thiab zaub mov qib Silicone raj.

Txais yuav Peristaltic twj tso kua mis:

Nws yog haum rau cov kua filling.Capping ib feem:

Muab lub puab ntsaws-muab lub hau-ntsia lub hau.Txais yuav magnetic torque screwing capping:

sealing caps nruj thiab tsis muaj mob rau lub kaus mom, capping nozzles yog customized raws li lub kaus mom

Tuam txhab profile

Shanghai Ipanda Intelligent Machinery Co. ltd yog lub chaw tsim khoom ntawm txhua yam khoom ntim khoom.Peb muab tag nrho cov kab ntau lawm suav nrog lub raj mis noj tshuab, filling tshuab, capping tshuab, labeling tshuab, packing tshuab thiab auxiliary khoom rau peb cov neeg muas zaub.

Kev pab cuam tom qab muag:

Peb lav qhov zoo ntawm cov khoom tseem ceeb hauv 12 lub hlis.Yog hais tias cov khoom tseem ceeb mus tsis ncaj ncees lawm yam tsis muaj khoom tsim nyob rau hauv ib xyoos, peb yuav pub dawb rau lawv los yog khaws cia rau koj.Tom qab ib xyoos, yog tias koj xav tau hloov qhov chaw, peb yuav ua siab zoo muab tus nqi zoo tshaj plaws rau koj lossis tswj nws hauv koj qhov chaw.Thaum twg koj muaj lus nug txog kev siv nws, peb yuav dawb do ua peb qhov zoo tshaj plaws los txhawb koj.

Kev lav zoo:

Tus neeg tsim khoom yuav tsum tau lees tias cov khoom yog tsim los ntawm Tuam Tshoj cov ntaub ntawv zoo tshaj plaws, nrog rau kev ua haujlwm hauv chav ua haujlwm thawj zaug, cov khoom tshiab, tsis siv thiab sib haum nrog txhua yam ntawm qhov zoo, qhov tshwj xeeb thiab kev ua tau zoo raws li tau teev tseg hauv Daim Ntawv Cog Lus no.Lub sijhawm lav zoo yog nyob rau hauv 12 lub hlis txij li hnub B / L.Lub Chaw Tsim Tshuaj yuav kho cov tshuab cog lus pub dawb thaum lub sijhawm lav zoo.Yog tias qhov kev tawg tuaj yeem yog vim kev siv tsis raug lossis lwm yam laj thawj los ntawm Tus Neeg Yuav Khoom, Lub Chaw Tsim Khoom yuav sau cov nqi kho qhov chaw.

Installation thiab Debugging:

Tus neeg muag khoom yuav xa nws cov engineers los qhia kev teeb tsa thiab kev debugging.Tus nqi yuav dais ntawm tus neeg yuav khoom sab (piv txwv li daim pib davhlau, nqi kev pab hauv lub tebchaws yuav khoom).Tus neeg yuav khoom yuav tsum muab nws qhov chaw pab rau lub installation thiab debuggingFAQ

Q1: Koj lub tuam txhab cov khoom tseem ceeb yog dab tsi?

Palletizer, Conveyors, Filling Ntau Lawm Kab, Sealing Machine, Cap ping Machine, Packing Machine, thiab Labeling Machine.

Q2: Hnub xa khoom ntawm koj cov khoom yog dab tsi?

Hnub xa khoom yog 30 hnub ua haujlwm feem ntau ntawm cov tshuab.

Q3: Lub sijhawm them nyiaj yog dab tsi?Tso nyiaj 30% ua ntej thiab 70% ua ntej xa khoom xa tuaj.

Q5: Koj nyob qhov twg?Nws puas yooj yim tuaj xyuas koj?Peb nyob hauv Shanghai.Kev khiav tsheb yooj yim heev.

Q6: Koj tuaj yeem lav qhov zoo li cas?

1.Peb tau ua tiav cov txheej txheem ua haujlwm thiab cov txheej txheem thiab peb ua raws li lawv nruj heev.

2.Peb cov neeg ua haujlwm sib txawv yog lub luag haujlwm rau cov txheej txheem ua haujlwm sib txawv, lawv txoj haujlwm tau lees paub, thiab yuav ua haujlwm txhua lub sijhawm, yog li kev paub dhau los.

3. Cov khoom siv hluav taws xob pneumatic yog los ntawm lub ntiaj teb nto moo tuam txhab, xws li lub teb chaws Yelemees ^ Siemens, Japanese Panasonic thiab lwm yam.

4. Peb yuav ua qhov kev sim nruj heev tom qab lub tshuab ua tiav.

5.0ur tshuab tau ntawv pov thawj los ntawm SGS, ISO.

Q7: Koj puas tuaj yeem tsim lub tshuab raws li peb xav tau?Yog lawm.Peb tsis tsuas yog tuaj yeem kho lub tshuab raws li koj qhov kev kos duab techni cal, tab sis kuj tuaj yeem ua nws lub tshuab tshiab raws li koj xav tau.

Q8: Koj puas tuaj yeem muab kev pab cuam txawv teb chaws?

Yog lawm.Peb tuaj yeem xa engineer rau koj lub tuam txhab los teeb lub tshuab thiab cob qhia koj.

-

Tsis Siv Neeg Qhov Muag Drop Filling Plugging Capping Tshuab

Txheej txheem cej luam:

Lub tshuab no yog siv los ntawm lub teb chaws Yelemees cov thev naus laus zis siab heev, lub tuam txhab engineering thiab cov neeg ua haujlwm txawj thiab lwm tus kheej tsim tshwj xeeb rau cov kua muag los yog e-kua filling stoppering capping tsim, sau qhov chaw ntawm lub tshuab txais peristaltic twj tso kua mis, PLC tswj, filling high precision, yooj yim los kho cov filling ntau, stopper thiab cap ib feem txais manipulator, capping ib feem siv sib nqus lub sij hawm capping sealing, sealing xov zoo nkauj, foob nrees.Lub tshuab tsim yog tsim nyog, ruaj khov thiab txhim khu kev qha, yooj yim rau kev khiav lag luam thiab tswj, ua raws li GMP cov cai, ntxiv rau cov khoom siv no Tsis muaj lub raj mis filling ua haujlwm nrog kuv lub tuam txhab rau lub tshuab ntxhua khaub ncaws, tshuab ntxhua khaub ncaws, qhov cub kom tsis muaj menyuam, lub teeb tshuaj xyuas tshuab , labeling tshuab thiab thiaj li nyob rau hauv ntau lawm kab linkage.

Kauj ruam ua haujlwm:

Tsis siv neeg pub rau lub raj mis-sau-tsis siv neeg pub rau lub hau / ntsaws-capping- tawm tso.Nta:

1. Lub tshuab filling thiab capping no yog ntau lub tshuab ua haujlwm monoblock nrog cov qauv tsim..

2. Lub tshuab no siv rau cov khoom noj khoom haus, khw muag tshuaj, tshuaj pleev ib ce, tshuaj thiab tshuaj tua kab.

4. Lub tshuab yog tswj los ntawm PLC thiab kov npo.

5. Nws siv Peristaltic twj tso kua mis filling system.

6. Yooj yim rau txhua yam capping taub hau, ntsia hlau, xovxwm, alu.Yob.

7. Nws yog cov cuab yeej zoo tshaj plaws rau kev muaj peev xwm tsawg.Nws tuaj yeem zawm lub kaus mom txiav.

8. Txhua qhov chaw uas kov cov khoom yog ua los ntawm cov hlau tsis zoo, thiab cov nplaim tau polished, tsis muaj kuab paug rau ib puag ncig.

Nws yog tsim rau cov khoom ntawm cov kua xws li e-kua, qhov muag poob, ntsia thawv polish thiab lwm yam. Nws yog dav siv rau kev sau cov khoom hauv kev lag luam xws li zaub mov, tshuaj pleev ib ce, tshuaj, roj, roj, kev lag luam tshuaj txhua hnub, tshuaj ntxuav tes, tshuaj tua kab thiab tshuaj lom neeg kev lag luam. lwm.

Parameters:

Siv tau specifications 1ml-200mml lossis customized Muaj peev xwm ntau lawm 30-40 Lub raj mis / min lossis 60-80BPM Filling raug ≤ ± 1% Fais fab mov 220V / 50Hz Rotating (rolling) npog tus nqi ≥99% Hwj chim 2.0 kwm Tshuab nqa hnyav 6 50kg Qhov ntev 2440 * 1700 * 1800 hli Txais SS304 filling nozzles thiab zaub mov qib Silicone raj.

Txais yuav Peristaltic twj tso kua mis:

Nws yog haum rau cov kua filling.Capping ib feem:

Muab lub puab ntsaws-muab lub hau-ntsia lub hau.Txais yuav magnetic torque screwing capping:

sealing caps nruj thiab tsis muaj mob rau lub kaus mom, capping nozzles yog customized raws li lub kaus mom

Tuam txhab profile

Peb tsom rau kev tsim ntau hom kev sau cov kab ntau lawm rau cov khoom sib txawv, xws li cov tshuaj ntsiav, kua, muab tshuaj, hmoov, aerosol, kua corrosive thiab lwm yam, uas tau siv dav hauv kev lag luam sib txawv, suav nrog zaub mov / dej haus / tshuaj pleev ib ce / petrochemicals thiab lwm yam. machines tag nrho customized raws li cov neeg siv khoom thiab thov.Lub tshuab ntim tshuab no yog tshiab hauv cov qauv, ruaj khov hauv kev ua haujlwm thiab yooj yim rau kev khiav lag luam. Zoo siab txais tos cov neeg siv khoom tshiab thiab qub tsab ntawv los sib tham txog kev txiav txim, kev tsim cov phooj ywg koom tes.Peb muaj cov neeg siv khoom hauv United States, Middle East, Southeast Asia, Russia thiab lwm yam thiab tau txais cov lus pom zoo los ntawm lawv nrog cov khoom zoo thiab cov kev pabcuam zoo.

Kev pab cuam tom qab muag:

Peb lav qhov zoo ntawm cov khoom tseem ceeb hauv 12 lub hlis.Yog hais tias cov khoom tseem ceeb mus tsis ncaj ncees lawm yam tsis muaj khoom tsim nyob rau hauv ib xyoos, peb yuav pub dawb rau lawv los yog khaws cia rau koj.Tom qab ib xyoos, yog tias koj xav tau hloov qhov chaw, peb yuav ua siab zoo muab tus nqi zoo tshaj plaws rau koj lossis tswj nws hauv koj qhov chaw.Thaum twg koj muaj lus nug txog kev siv nws, peb yuav dawb do ua peb qhov zoo tshaj plaws los txhawb koj.

Kev lav zoo:

Tus neeg tsim khoom yuav tsum tau lees tias cov khoom yog tsim los ntawm Tuam Tshoj cov ntaub ntawv zoo tshaj plaws, nrog rau kev ua haujlwm hauv chav ua haujlwm thawj zaug, cov khoom tshiab, tsis siv thiab sib haum nrog txhua yam ntawm qhov zoo, qhov tshwj xeeb thiab kev ua tau zoo raws li tau teev tseg hauv Daim Ntawv Cog Lus no.Lub sijhawm lav zoo yog nyob rau hauv 12 lub hlis txij li hnub B / L.Lub Chaw Tsim Tshuaj yuav kho cov tshuab cog lus pub dawb thaum lub sijhawm lav zoo.Yog tias qhov kev tawg tuaj yeem yog vim kev siv tsis raug lossis lwm yam laj thawj los ntawm Tus Neeg Yuav Khoom, Lub Chaw Tsim Khoom yuav sau cov nqi kho qhov chaw.

Installation thiab Debugging:

Tus neeg muag khoom yuav xa nws cov engineers los qhia kev teeb tsa thiab kev debugging.Tus nqi yuav dais ntawm tus neeg yuav khoom sab (piv txwv li daim pib davhlau, nqi kev pab hauv lub tebchaws yuav khoom).Tus neeg yuav khoom yuav tsum muab nws qhov chaw pab rau lub installation thiab debuggingFAQ

Q1: Koj lub tuam txhab cov khoom tseem ceeb yog dab tsi?

Palletizer, Conveyors, Filling Ntau Lawm Kab, Sealing Machine, Cap ping Machine, Packing Machine, thiab Labeling Machine.

Q2: Hnub xa khoom ntawm koj cov khoom yog dab tsi?

Hnub xa khoom yog 30 hnub ua haujlwm feem ntau ntawm cov tshuab.

Q3: Lub sijhawm them nyiaj yog dab tsi?Tso nyiaj 30% ua ntej thiab 70% ua ntej xa khoom xa tuaj.

Q5: Koj nyob qhov twg?Nws puas yooj yim tuaj xyuas koj?Peb nyob hauv Shanghai.Kev khiav tsheb yooj yim heev.

Q6: Koj tuaj yeem lav qhov zoo li cas?

1.Peb tau ua tiav cov txheej txheem ua haujlwm thiab cov txheej txheem thiab peb ua raws li lawv nruj heev.

2.Peb cov neeg ua haujlwm sib txawv yog lub luag haujlwm rau cov txheej txheem ua haujlwm sib txawv, lawv txoj haujlwm tau lees paub, thiab yuav ua haujlwm txhua lub sijhawm, yog li kev paub dhau los.

3. Cov khoom siv hluav taws xob pneumatic yog los ntawm lub ntiaj teb nto moo tuam txhab, xws li lub teb chaws Yelemees ^ Siemens, Japanese Panasonic thiab lwm yam.

4. Peb yuav ua qhov kev sim nruj heev tom qab lub tshuab ua tiav.

5.0ur tshuab tau ntawv pov thawj los ntawm SGS, ISO.

Q7: Koj puas tuaj yeem tsim lub tshuab raws li peb xav tau?Yog lawm.Peb tsis tsuas yog tuaj yeem kho lub tshuab raws li koj qhov kev kos duab techni cal, tab sis kuj tuaj yeem ua nws lub tshuab tshiab raws li koj xav tau.

Q8: Koj puas tuaj yeem muab kev pab cuam txawv teb chaws?

Yog lawm.Peb tuaj yeem xa engineer rau koj lub tuam txhab los teeb lub tshuab thiab cob qhia koj.

-

Tsis Siv Neeg Qhov Muag Drop Mini Lub raj mis Ua Kua Filling Tshuab

Txheej txheem cej luam:

Qhov no lub qhov muag tee filling thiab capping tshuab yog peb cov khoom ib txwm muaj, thiab raws li cov neeg siv khoom xav tau, peb muaj qee qhov kev tsim kho tshiab rau lub tshuab no.Qhov chaw & tracing filling yog saws rau 1 / 2 / 4 nozzles filling & capping tshuab, thiab cov khoom tsim tau txaus siab rau cov neeg siv.Tus pass tus nqi yog siab.Thiab raws li cov neeg siv khoom xav tau, lub tshuab ntxhua khaub ncaws / ziab khaub ncaws sib txuas lossis tshuab tshuab tuaj yeem txuas nrog.

Nta:

1.Txhua cov ntaub ntawv hauv kev sib cuag nrog cov khoom yog ntawm 316L stainless hlau thiab cov ntsaws ruaj ruaj yog ua los ntawm cov khoom noj khoom haus qib.

thiab lwm yam siv los ntawm 304L stainless hlau

2.Lub filling precision yog siab.

3.Lub hau ntsia hlau tuaj yeem kho tau ntau lub hau.

4. Siv SIEMENS, Shcnider, Yooj yim rau kev khiav lag luam

Nrog peb cov thev naus laus zis thev naus laus zis thiab kev paub nplua nuj, peb yuav muab cov kev daws teeb meem rau koj qhov kev xav tau.Nws yuav ua kom koj cov haujlwm yooj yim.Parameters:

Siv lub raj mis 10-120 ml Productive Capacity 30-100pcs / min Filling Precision 0-1% Tsim nyog nres ≥99% Tsim nyog cap muab ≥99% Tsim nyog capping ≥99% Fais fab mov 380V, 50Hz / 220V, 50Hz (kev cai) Hwj chim 2.5 KW TSI Net nyhav 600 KG Dimension 2100 (L) * 1200 (W) * 1850 (H) hli Txais SS304 filling nozzles thiab zaub mov qib Silicone raj.

Txais yuav Peristaltic twj tso kua mis:

Nws yog haum rau cov kua filling.Capping ib feem:

Muab lub puab ntsaws-muab lub hau-ntsia lub hau.Txais yuav magnetic torque screwing capping:

sealing caps nruj thiab tsis muaj mob rau lub kaus mom, capping nozzles yog customized raws li lub kaus mom

Tuam txhab profile

Shanghai Ipanda Intelligent Machinery Co. ltd yog lub chaw tsim khoom ntawm txhua yam khoom ntim khoom.Peb muab tag nrho cov kab ntau lawm suav nrog lub raj mis noj tshuab, filling tshuab, capping tshuab, labeling tshuab, packing tshuab thiab auxiliary khoom rau peb cov neeg muas zaub.

Kev pab cuam tom qab muag:

Peb lav qhov zoo ntawm cov khoom tseem ceeb hauv 12 lub hlis.Yog hais tias cov khoom tseem ceeb mus tsis ncaj ncees lawm yam tsis muaj khoom tsim nyob rau hauv ib xyoos, peb yuav pub dawb rau lawv los yog khaws cia rau koj.Tom qab ib xyoos, yog tias koj xav tau hloov qhov chaw, peb yuav ua siab zoo muab tus nqi zoo tshaj plaws rau koj lossis tswj nws hauv koj qhov chaw.Thaum twg koj muaj lus nug txog kev siv nws, peb yuav dawb do ua peb qhov zoo tshaj plaws los txhawb koj.

Kev lav zoo:

Tus neeg tsim khoom yuav tsum tau lees tias cov khoom yog tsim los ntawm Tuam Tshoj cov ntaub ntawv zoo tshaj plaws, nrog rau kev ua haujlwm hauv chav ua haujlwm thawj zaug, cov khoom tshiab, tsis siv thiab sib haum nrog txhua yam ntawm qhov zoo, qhov tshwj xeeb thiab kev ua tau zoo raws li tau teev tseg hauv Daim Ntawv Cog Lus no.Lub sijhawm lav zoo yog nyob rau hauv 12 lub hlis txij li hnub B / L.Lub Chaw Tsim Tshuaj yuav kho cov tshuab cog lus pub dawb thaum lub sijhawm lav zoo.Yog tias qhov kev tawg tuaj yeem yog vim kev siv tsis raug lossis lwm yam laj thawj los ntawm Tus Neeg Yuav Khoom, Lub Chaw Tsim Khoom yuav sau cov nqi kho qhov chaw.

Installation thiab Debugging:

Tus neeg muag khoom yuav xa nws cov engineers los qhia kev teeb tsa thiab kev debugging.Tus nqi yuav dais ntawm tus neeg yuav khoom sab (piv txwv li daim pib davhlau, nqi kev pab hauv lub tebchaws yuav khoom).Tus neeg yuav khoom yuav tsum muab nws qhov chaw pab rau lub installation thiab debuggingFAQ

Q1: Koj lub tuam txhab cov khoom tseem ceeb yog dab tsi?

Palletizer, Conveyors, Filling Ntau Lawm Kab, Sealing Machine, Cap ping Machine, Packing Machine, thiab Labeling Machine.

Q2: Hnub xa khoom ntawm koj cov khoom yog dab tsi?

Hnub xa khoom yog 30 hnub ua haujlwm feem ntau ntawm cov tshuab.

Q3: Lub sijhawm them nyiaj yog dab tsi?Tso nyiaj 30% ua ntej thiab 70% ua ntej xa khoom xa tuaj.

Q5: Koj nyob qhov twg?Nws puas yooj yim tuaj xyuas koj?Peb nyob hauv Shanghai.Kev khiav tsheb yooj yim heev.

Q6: Koj tuaj yeem lav qhov zoo li cas?

1.Peb tau ua tiav cov txheej txheem ua haujlwm thiab cov txheej txheem thiab peb ua raws li lawv nruj heev.

2.Peb cov neeg ua haujlwm sib txawv yog lub luag haujlwm rau cov txheej txheem ua haujlwm sib txawv, lawv txoj haujlwm tau lees paub, thiab yuav ua haujlwm txhua lub sijhawm, yog li kev paub dhau los.

3. Cov khoom siv hluav taws xob pneumatic yog los ntawm lub ntiaj teb nto moo tuam txhab, xws li lub teb chaws Yelemees ^ Siemens, Japanese Panasonic thiab lwm yam.

4. Peb yuav ua qhov kev sim nruj heev tom qab lub tshuab ua tiav.

5.0ur tshuab tau ntawv pov thawj los ntawm SGS, ISO.

Q7: Koj puas tuaj yeem tsim lub tshuab raws li peb xav tau?Yog lawm.Peb tsis tsuas yog tuaj yeem kho lub tshuab raws li koj qhov kev kos duab techni cal, tab sis kuj tuaj yeem ua nws lub tshuab tshiab raws li koj xav tau.

Q8: Koj puas tuaj yeem muab kev pab cuam txawv teb chaws?

Yog lawm.Peb tuaj yeem xa engineer rau koj lub tuam txhab los teeb lub tshuab thiab cob qhia koj.

-

Tsis Siv Neeg Qhov Muag Drop Bottle Filling Stoppering Capping Tshuab Chaw tsim tshuaj paus

Txheej txheem cej luam:

Lub tshuab filling thiab capping tsis siv neeg yog cov cuab yeej tsim los rau cov kua fwj.Nws siv Peristaltic twj tso kua mis filling, positioning type cap feeder, capping, thiab magnetic moment capping.Siv PLC, kov npo tswj, imported photoelectric nrhiav tau, siab precision, dav siv nyob rau hauv kws, zaub mov, tshuaj, khoom kho mob, tshuaj tua kab thiab lwm yam lag luam.Ua raws li kev ua raws li GMP tshiab.

Kauj ruam ua haujlwm:

Tsis siv neeg pub rau lub raj mis-sau-tsis siv neeg pub rau lub hau / ntsaws-capping- tawm tso.

feature:

1.Adopt human-computer interface, PLC maub los, yooj yim rau kev khiav lag luam

2.Siv zaus converting tswj, yooj yim los kho cov filling ceev, tsis siv neeg suav

3. Tsis siv neeg nres, tsis muaj lub raj mis filling.

4.Round tig lub rooj rau positioning filling, ruaj khov thiab txhim khu kev qha.

5.High precision CAM indexing gage tswj.Parameters:

Siv lub raj mis 10-120 ml Productive Capacity 30-100pcs / min Filling Precision 0-1% Tsim nyog nres ≥99% Tsim nyog cap muab ≥99% Tsim nyog capping ≥99% Fais fab mov 380V, 50Hz / 220V, 50Hz (kev cai) Hwj chim 2.5 KW TSI Net nyhav 600 KG Dimension 2100 (L) * 1200 (W) * 1850 (H) hli Txais SS304 filling nozzles thiab zaub mov qib Silicone raj.

Txais yuav Peristaltic twj tso kua mis:

Nws yog haum rau cov kua filling.Capping ib feem:

Muab lub puab ntsaws-muab lub hau-ntsia lub hau.Txais yuav magnetic torque screwing capping:

sealing caps nruj thiab tsis muaj mob rau lub kaus mom, capping nozzles yog customized raws li lub kaus mom

Kev teeb tsa

Tus tsim tawm: Schneider

Switching Power Supply: Schneider

AC Contactor: Schneider

Khawm: Schneider

Lub tswb nrov: Schneider

PLC: Siemens

Kov Screen: Simens

Lub tog raj kheej: Airta

Servo Tsav: Schneider

Dej Seperator: Airtac

Electromagnetic Valve: Airtac

Kev soj ntsuam pom: COGNEX

Zaus Converter: Schneider

Detection Photoelectric: SICK

Tuam txhab profile

Peb tsom rau kev tsim ntau hom kev sau cov kab ntau lawm rau cov khoom sib txawv, xws li cov tshuaj ntsiav, kua, muab tshuaj, hmoov, aerosol, kua corrosive thiab lwm yam, uas tau siv dav hauv kev lag luam sib txawv, suav nrog zaub mov / dej haus / tshuaj pleev ib ce / petrochemicals thiab lwm yam. machines tag nrho customized raws li cov neeg siv khoom thiab thov.Lub tshuab ntim tshuab no yog tshiab hauv cov qauv, ruaj khov hauv kev ua haujlwm thiab yooj yim rau kev khiav lag luam. Zoo siab txais tos cov neeg siv khoom tshiab thiab qub tsab ntawv los sib tham txog kev txiav txim, kev tsim cov phooj ywg koom tes.Peb muaj cov neeg siv khoom hauv United States, Middle East, Southeast Asia, Russia thiab lwm yam thiab tau txais cov lus pom zoo los ntawm lawv nrog cov khoom zoo thiab cov kev pabcuam zoo.

Kev pab cuam tom qab muag:

Peb lav qhov zoo ntawm cov khoom tseem ceeb hauv 12 lub hlis.Yog hais tias cov khoom tseem ceeb mus tsis ncaj ncees lawm yam tsis muaj khoom tsim nyob rau hauv ib xyoos, peb yuav pub dawb rau lawv los yog khaws cia rau koj.Tom qab ib xyoos, yog tias koj xav tau hloov qhov chaw, peb yuav ua siab zoo muab tus nqi zoo tshaj plaws rau koj lossis tswj nws hauv koj qhov chaw.Thaum twg koj muaj lus nug txog kev siv nws, peb yuav dawb do ua peb qhov zoo tshaj plaws los txhawb koj.

Kev lav zoo:

Tus neeg tsim khoom yuav tsum tau lees tias cov khoom yog tsim los ntawm Tuam Tshoj cov ntaub ntawv zoo tshaj plaws, nrog rau kev ua haujlwm hauv chav ua haujlwm thawj zaug, cov khoom tshiab, tsis siv thiab sib haum nrog txhua yam ntawm qhov zoo, qhov tshwj xeeb thiab kev ua tau zoo raws li tau teev tseg hauv Daim Ntawv Cog Lus no.Lub sijhawm lav zoo yog nyob rau hauv 12 lub hlis txij li hnub B / L.Lub Chaw Tsim Tshuaj yuav kho cov tshuab cog lus pub dawb thaum lub sijhawm lav zoo.Yog tias qhov kev tawg tuaj yeem yog vim kev siv tsis raug lossis lwm yam laj thawj los ntawm Tus Neeg Yuav Khoom, Lub Chaw Tsim Khoom yuav sau cov nqi kho qhov chaw.

Installation thiab Debugging:

Tus neeg muag khoom yuav xa nws cov engineers los qhia kev teeb tsa thiab kev debugging.Tus nqi yuav dais ntawm tus neeg yuav khoom sab (piv txwv li daim pib davhlau, nqi kev pab hauv lub tebchaws yuav khoom).Tus neeg yuav khoom yuav tsum muab nws qhov chaw pab rau lub installation thiab debuggingFAQ

.

Q1.Cov nqe lus them nqi thiab nqe lus ua lag luam yog dab tsi rau cov neeg siv khoom tshiab?

A1: Cov nqe lus them nqi: T / T, L / C, D / P, thiab lwm yam.

Cov ntsiab lus lag luam: EXW, FOB, CIF.CFR thiab lwm yam.Q2: Yam kev thauj mus los twg koj tuaj yeem muab tau?Thiab koj puas tuaj yeem hloov kho cov txheej txheem ntau lawm Cov ntaub ntawv hauv lub sijhawm tom qab tso peb qhov kev txiav txim?

A2: Hiav txwv shipping, huab cua Shipping, thiab thoob ntiaj teb nthuav qhia.Thiab tom qab lees paub koj qhov kev txiav txim, peb yuav ua kom koj hloov kho cov ntsiab lus ntawm email thiab duab.

Q3: Yam tsawg kawg nkaus Order Quantity thiab warranty?

A3: MOQ: 1set

Warranty: Peb muab koj cov tshuab zoo nrog 12 lub hlis lav thiab muab kev pabcuam raws sijhawmQ4: Koj puas muab kev pabcuam customized?

A4: Yog lawm, Peb muaj cov kws tshaj lij engineers uas muaj kev paub zoo hauv kev lag luam no tau ntau xyoo, lawv muab cov lus pom zoo suav nrog cov tshuab tsim, ua tiav cov kab hauv qab ntawm koj qhov project peev xwm, kev teeb tsa kev thov, thiab lwm yam, kom ua tiav cov neeg siv khoom xav tau hauv kev ua lag luam.

Q5.: Koj puas muab cov khoom siv hlau thiab muab kev cob qhia rau peb?

A5: Hnav cov khoom, piv txwv li, siv lub cev muaj zog, Disassembly tool (dawb) yog qhov peb tuaj yeem muab tau.Thiab peb tuaj yeem muab kev qhia rau koj. -

High Speed Automatic Eye Drop Liquid Filling Tshuab

Txheej txheem cej luam:

Lub taub hau hau taub hau siv lub zog tas li, tsis siv neeg plam ping ntaus ntawv, yuav tsis zom lub hau lub raj mis, lub raj mis yuav tsis ua raws, yuav tsis ua rau lub raj mis puas.Nrog rau qhov tseeb qhov chaw, tsis muaj lub raj mis tsis sau, kev sib kis tau yooj yim, kev ua haujlwm yooj yim thiab lwm yam.Tabletops, nyob ib ncig ntawm lub rooj tsavxwm yog imported 304 zoo stainless hlau, nrog rau cov kua tiv tauj ib feem ntawm 316L stainless hlau, tag nrho cov tshuab nyob rau hauv txoj kab nrog GMP cov kev cai.Cov kab ntau lawm kis tau tus mob yog mechanical kis tau tus mob, kis tau tus mob yog, du, gas-dawb paug thiab ntau lub tsev tsis muaj kev ua yuam kev thiab lwm yam phenomena.Thaum ua haujlwm, lub suab nrov qis, qhov poob qis, kev ua haujlwm ruaj khov, cov zis ruaj khov, tshwj xeeb tshaj yog tsim rau batch ntau lawm.

Nta:

1.Txhua cov ntaub ntawv hauv kev sib cuag nrog cov khoom yog ntawm 316L stainless hlau thiab cov ntsaws ruaj ruaj yog ua los ntawm cov khoom noj khoom haus qib.

thiab lwm yam siv los ntawm 304L stainless hlau

2.Lub filling precision yog siab.

3.Lub hau ntsia hlau tuaj yeem kho tau ntau lub hau.

4. Siv SIEMENS, Shcnider, Yooj yim rau kev khiav lag luam

Nrog peb cov thev naus laus zis thev naus laus zis thiab kev paub nplua nuj, peb yuav muab cov kev daws teeb meem rau koj qhov kev xav tau.Nws yuav ua kom koj cov haujlwm yooj yim.Parameters:

Siv lub raj mis 10-120 ml Productive Capacity 30-100pcs / min Filling Precision 0-1% Tsim nyog nres ≥99% Tsim nyog cap muab ≥99% Tsim nyog capping ≥99% Fais fab mov 380V, 50Hz / 220V, 50Hz (kev cai) Hwj chim 2.5 KW TSI Net nyhav 600 KG Dimension 2100 (L) * 1200 (W) * 1850 (H) hli Txais SS304 filling nozzles thiab zaub mov qib Silicone raj.

Txais yuav Peristaltic twj tso kua mis:

Nws yog haum rau cov kua filling.Capping ib feem:

Muab lub puab ntsaws-muab lub hau-ntsia lub hau.Txais yuav magnetic torque screwing capping:

sealing caps nruj thiab tsis muaj mob rau lub kaus mom, capping nozzles yog customized raws li lub kaus mom

Kev teeb tsa

Tus tsim tawm: Schneider

Switching Power Supply: Schneider

AC Contactor: Schneider

Khawm: Schneider

Lub tswb nrov: Schneider

PLC: Siemens

Kov Screen: Simens

Lub tog raj kheej: Airta

Servo Tsav: Schneider

Dej Seperator: Airtac

Electromagnetic Valve: Airtac

Kev soj ntsuam pom: COGNEX

Zaus Converter: Schneider

Detection Photoelectric: SICK

Tuam txhab profile

Shanghai Ipanda Intelligent Machinery Co., Ltd. yog lub tuam txhab kev lag luam tshwj xeeb hauv kev tsim, tsim khoom, R & D, kev lag luam ntawm cov khoom ntim thiab ntim khoom.Our R & D thiab tsim pab pawg muaj ntau tshaj 10 xyoo ntawm kev paub hauv kev lag luam filling.Peb lub Hoobkas npog thaj tsam ntawm 5000 square metres, tam sim no nws muaj lub Hoobkas thib ob ua chav ua yeeb yam, uas suav nrog kev ua tiav cov kab ntau lawm rau cov khoom ntim hauv cov tshuaj txhua hnub, tshuaj, petrochemical, thiab zaub mov kev lag luam.

Kev pab cuam tom qab muag:

Peb lav qhov zoo ntawm cov khoom tseem ceeb hauv 12 lub hlis.Yog hais tias cov khoom tseem ceeb mus tsis ncaj ncees lawm yam tsis muaj khoom tsim nyob rau hauv ib xyoos, peb yuav pub dawb rau lawv los yog khaws cia rau koj.Tom qab ib xyoos, yog tias koj xav tau hloov qhov chaw, peb yuav ua siab zoo muab tus nqi zoo tshaj plaws rau koj lossis tswj nws hauv koj qhov chaw.Thaum twg koj muaj lus nug txog kev siv nws, peb yuav dawb do ua peb qhov zoo tshaj plaws los txhawb koj.

Kev lav zoo:

Tus neeg tsim khoom yuav tsum tau lees tias cov khoom yog tsim los ntawm Tuam Tshoj cov ntaub ntawv zoo tshaj plaws, nrog rau kev ua haujlwm hauv chav ua haujlwm thawj zaug, cov khoom tshiab, tsis siv thiab sib haum nrog txhua yam ntawm qhov zoo, qhov tshwj xeeb thiab kev ua tau zoo raws li tau teev tseg hauv Daim Ntawv Cog Lus no.Lub sijhawm lav zoo yog nyob rau hauv 12 lub hlis txij li hnub B / L.Lub Chaw Tsim Tshuaj yuav kho cov tshuab cog lus pub dawb thaum lub sijhawm lav zoo.Yog tias qhov kev tawg tuaj yeem yog vim kev siv tsis raug lossis lwm yam laj thawj los ntawm Tus Neeg Yuav Khoom, Lub Chaw Tsim Khoom yuav sau cov nqi kho qhov chaw.

Installation thiab Debugging:

Tus neeg muag khoom yuav xa nws cov engineers los qhia kev teeb tsa thiab kev debugging.Tus nqi yuav dais ntawm tus neeg yuav khoom sab (piv txwv li daim pib davhlau, nqi kev pab hauv lub tebchaws yuav khoom).Tus neeg yuav khoom yuav tsum muab nws qhov chaw pab rau lub installation thiab debuggingFAQ

Q1.Koj puas yog manufactory?

A1: Yog, Peb yog cov chaw tsim khoom ntawm filling-capping-labeling-lub raj mis ntxhua khaub ncaws, thiab ua tiav kab, Peb lub Hoobkas nyob ze Shanghai, nyob hauv Xuzhou, Jiangsu Province.Q2.Cov nqe lus them nqi thiab nqe lus ua lag luam yog dab tsi rau cov neeg siv khoom tshiab?

A2: Cov nqe lus them nqi: T / T, L / C, D / P, thiab lwm yam.

Cov ntsiab lus kev lag luam: EXW, FOB, CIF.Q3: Yam tsawg kawg nkaus Order Quantity thiab warranty?

A3: MOQ: 1set

Warranty: Peb muab koj cov tshuab zoo nrog 12 lub hlis lav thiab muab kev pabcuam raws sijhawmQ4: Koj puas muab kev pabcuam customized?

A4: Yog lawm, Peb muaj cov kws tshaj lij engineers uas muaj kev paub zoo hauv kev lag luam no tau ntau xyoo, lawv muab cov lus pom zoo suav nrog cov tshuab tsim, ua tiav cov kab hauv qab ntawm koj qhov project peev xwm, kev teeb tsa kev thov, thiab lwm yam, kom ua tiav cov neeg siv khoom xav tau hauv kev ua lag luam. -

Tsis Siv Neeg Me Me Qhov Muag Drops Lub raj mis Ua Kua Filling Capping Tshuab

Txheej txheem cej luam:

Qhov no lub qhov muag tee filling thiab capping tshuab yog peb cov khoom ib txwm muaj, thiab raws li cov neeg siv khoom xav tau, peb muaj qee qhov kev tsim kho tshiab rau lub tshuab no.Qhov chaw & tracing filling yog saws rau 1 / 2 / 4 nozzles filling & capping tshuab, thiab cov khoom tsim tau txaus siab rau cov neeg siv.Tus pass tus nqi yog siab.Thiab raws li cov neeg siv khoom xav tau, lub tshuab ntxhua khaub ncaws / ziab khaub ncaws sib txuas lossis tshuab tshuab tuaj yeem txuas nrog.

Nta:

1. Lub tshuab filling thiab capping no yog ntau lub tshuab ua haujlwm monoblock nrog cov qauv tsim..

2. Lub tshuab no siv rau cov khoom noj khoom haus, khw muag tshuaj, tshuaj pleev ib ce, tshuaj thiab tshuaj tua kab.

4. Lub tshuab yog tswj los ntawm PLC thiab kov npo.

5. Nws siv Peristaltic twj tso kua mis filling system.

6. Yooj yim rau txhua yam capping taub hau, ntsia hlau, xovxwm, alu.Yob.

7. Nws yog cov cuab yeej zoo tshaj plaws rau kev muaj peev xwm tsawg.Nws tuaj yeem zawm lub kaus mom txiav.

8. Txhua qhov chaw uas kov cov khoom yog ua los ntawm cov hlau tsis zoo, thiab cov nplaim tau polished, tsis muaj kuab paug rau ib puag ncig.

Parameters:

Siv lub raj mis 10-120 ml Productive Capacity 30-100pcs / min Filling Precision 0-1% Tsim nyog nres ≥99% Tsim nyog cap muab ≥99% Tsim nyog capping ≥99% Fais fab mov 380V, 50Hz / 220V, 50Hz (kev cai) Hwj chim 2.5 KW TSI Net nyhav 600 KG Dimension 2100 (L) * 1200 (W) * 1850 (H) hli -

Customize Txais Tsis Siv Neeg 4 Nozzles Eliquid thiab Eye Drop Filling Tshuab

Txheej txheem cej luam:

Qhov no lub qhov muag tee filling thiab capping tshuab yog peb cov khoom ib txwm muaj, thiab raws li cov neeg siv khoom xav tau, peb muaj qee qhov kev tsim kho tshiab rau lub tshuab no.Qhov chaw & tracing filling yog saws rau 1 / 2 / 4 nozzles filling & capping tshuab, thiab cov khoom tsim tau txaus siab rau cov neeg siv.Tus pass tus nqi yog siab.Thiab raws li cov neeg siv khoom xav tau, lub tshuab ntxhua khaub ncaws / ziab khaub ncaws sib txuas lossis tshuab tshuab tuaj yeem txuas nrog.

Nta:

1. Lub tshuab filling thiab capping no yog ntau lub tshuab ua haujlwm monoblock nrog cov qauv tsim..

2. Lub tshuab no siv rau cov khoom noj khoom haus, khw muag tshuaj, tshuaj pleev ib ce, tshuaj thiab tshuaj tua kab.

4. Lub tshuab yog tswj los ntawm PLC thiab kov npo.

5. Nws siv Peristaltic twj tso kua mis filling system.

6. Yooj yim rau txhua yam capping taub hau, ntsia hlau, xovxwm, alu.Yob.

7. Nws yog cov cuab yeej zoo tshaj plaws rau kev muaj peev xwm tsawg.Nws tuaj yeem zawm lub kaus mom txiav.

8. Txhua qhov chaw uas kov cov khoom yog ua los ntawm cov hlau tsis zoo, thiab cov nplaim tau polished, tsis muaj kuab paug rau ib puag ncig.

Parameters:

Siv lub raj mis 10-120 ml Productive Capacity 30-100pcs / min Filling Precision 0-1% Tsim nyog nres ≥99% Tsim nyog cap muab ≥99% Tsim nyog capping ≥99% Fais fab mov 380V, 50Hz / 220V, 50Hz (kev cai) Hwj chim 2.5 KW TSI Net nyhav 600 KG Dimension 2100 (L) * 1200 (W) * 1850 (H) hli