Tsis Siv Neeg Me Me Cov Kab Ntau Lawm Kom Zoo Nkauj Nail Polish Filling Capping Tshuab

Lub tshuab no yog tsim rau me me ua kua ntim cov kab ntau lawm hauv cov tshuaj pleev ib ce, tshuaj txhua hnub thiab kev lag luam tshuaj thiab lwm yam, tuaj yeem ua tiav puv, ntsaws, ntsia hlau hau, dov cap, capping, bottling thiab lwm yam txheej txheem.Lub tshuab tag nrho yog ua los ntawm SUS304 stainless hlau. thiab tib qib aluminium alloy kho los ntawm qib zoo, tsis txhob xeb, ua raws li GMP tus qauv.

Cov cuab yeej zoo tagnrho rau ntim cov ntim me me, peb kho lub tshuab rau qhov sib txawv thiab cov duab ntawm lub raj mis, ob lub khob thiab yas yog OK.Nws yog dav siv hauv Tshuaj pleev ib ce (tseem ceeb roj, naj hoom, ntsia thawv polish, qhov muag poob thiab lwm yam) tshuaj (iav nplaum, sealant, dawb latex, thiab lwm yam) industries thiab lwm yam.

| Ntim ntim | 10ml ~ 250ml |

| Haum txoj kab uas hla ntawm lub raj mis | φ15mm ~ φ100mm |

| Ntsuas precision | ± 0.01% (≤200ml) |

| Muaj peev xwm ntau lawm | ≤ 2000 fwj / teev |

| Cua siab | 0.6 ~ 0.8MPa |

| Tus nqi ntawm Airconsuming | 200 l / min |

| Fais fab mov | AC 220V / 50Hz (Customized) |

| Hwj chim | 2.5 kwb |

| Tshuab hnyav | Txog 800Kg |

| Tshuab dimension (L × W × H) | 2000mm × 2000mm × 2100mm |

1. Lub tshuab no siv lub hau ntswj ntsia hlau tas li, nruab nrog cov khoom siv zawv zawg tsis siv neeg, txhawm rau tiv thaiv lub hau kev puas tsuaj.

2. Peristaltic twj tso kua mis filling, ntsuas precision, yooj yim manipulation.

3. Filling system muaj nuj nqi ntawm nqus rov qab, tsis txhob ua kua los ntawm.

4. Xim kov npo zaub, PLC tswj qhov system, tsis muaj lub raj mis filling, tsis ntxiv ntsaws, tsis muaj capping.

5. Filling nozzle yog tsim los ntawm 316 stainless hlau, tshuab lub cev yog tsim los ntawm 304 stainless hlau, yooj yim rau dismantle thiab huv si, tag nrho ua raws li GMP cov cai.

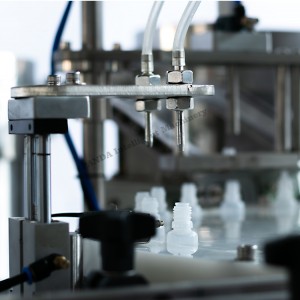

Filling ntu:

Txais SS304 filling nozzles thiab zaub mov qib Silicone raj.It tau raws li CE Standard.Filling nozzle dhia mus rau hauv lub raj mis kom sau thiab maj mam nce kom tsis txhob muaj foaming.

Peristaltic twj tso kua mis filling, ntsuas precision, yooj yim manipulation;

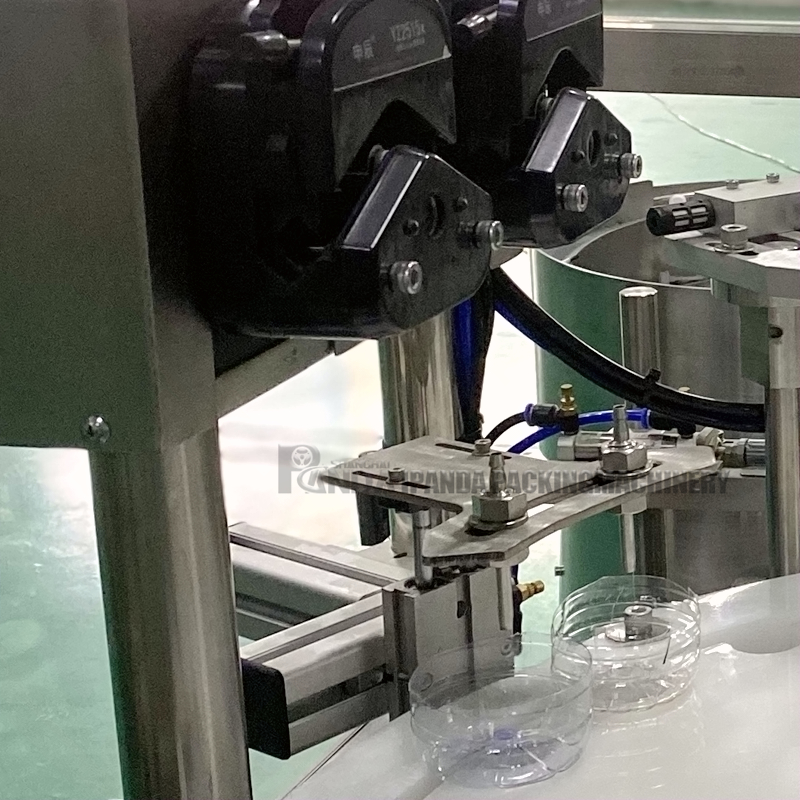

Capping ib feem:Muab cov txhuam txhuam-- Muab lub hau-Screw cap

Kev pab cuam tom qab muag:

Peb lav qhov zoo ntawm cov khoom tseem ceeb hauv 12 lub hlis.Yog hais tias cov khoom tseem ceeb mus tsis ncaj ncees lawm yam tsis muaj khoom tsim nyob rau hauv ib xyoos, peb yuav pub dawb rau lawv los yog khaws cia rau koj.Tom qab ib xyoos, yog tias koj xav tau hloov qhov chaw, peb yuav ua siab zoo muab tus nqi zoo tshaj plaws rau koj lossis tswj nws hauv koj qhov chaw.Thaum twg koj muaj lus nug txog kev siv nws, peb yuav dawb do ua peb qhov zoo tshaj plaws los txhawb koj.

Guarantee ntawm qhov zoo:

Tus neeg tsim khoom yuav tsum tau lees tias cov khoom yog tsim los ntawm Tuam Tshoj cov ntaub ntawv zoo tshaj plaws, nrog rau kev ua haujlwm hauv chav ua haujlwm thawj zaug, cov khoom tshiab, tsis siv thiab sib haum nrog txhua yam ntawm qhov zoo, qhov tshwj xeeb thiab kev ua tau zoo raws li tau teev tseg hauv Daim Ntawv Cog Lus no.Lub sijhawm lav zoo yog nyob rau hauv 12 lub hlis txij li hnub B / L.Lub Chaw Tsim Tshuaj yuav kho cov tshuab cog lus pub dawb thaum lub sijhawm lav zoo.Yog tias qhov kev tawg tuaj yeem yog vim kev siv tsis raug lossis lwm yam laj thawj los ntawm Tus Neeg Yuav Khoom, Lub Chaw Tsim Khoom yuav sau cov nqi kho qhov chaw.

Installation thiab Debugging:

Tus neeg muag khoom yuav xa nws cov engineers los qhia kev teeb tsa thiab kev debugging.Tus nqi yuav dais ntawm tus neeg yuav khoom sab (piv txwv li daim pib davhlau, nqi kev pab hauv lub tebchaws yuav khoom).Tus neeg yuav khoom yuav tsum muab nws qhov chaw pab rau lub installation thiab debugging.rov qab, tsis txhob ua kua los ntawm;

1. Xim kov npo zaub, PLC tswj qhov system, tsis muaj lub raj mis filling, tsis ntxiv ntsaws, tsis muaj capping;

2. Ntxiv cov khoom ntsaws tuaj yeem xaiv cov pwm ruaj khov lossis cov tshuab nqus tsev pwm;

3. Tshuab yog tsim los ntawm 316 thiab 304 stainless hlau, yooj yim rau dismantle thiab huv si, tag nrho ua raws li GMP cov cai.

4. Kev koom ua ke nrog txhua yam, hluav taws xob & pneumatic system, lub monoblock tsim yog tsawg qhov chaw noj, txhim khu kev qha & kev lag luam, nrog kev yoog raws thiab siab automation, tshwj xeeb tshaj yog zoo rau OEM, ODM cov khoom & tsis loj scale pib ntau lawm;

FAQ

Q1: Koj lub tuam txhab cov khoom tseem ceeb yog dab tsi?

Palletizer, Conveyors, Filling Ntau Lawm Kab, Sealing Machine, Cap ping Machine, Packing Machine, thiab Labeling Machine.

Q2: Hnub xa khoom ntawm koj cov khoom yog dab tsi?

Hnub xa khoom yog 30 hnub ua haujlwm feem ntau ntawm cov tshuab.

Q3: Lub sijhawm them nyiaj yog dab tsi?Tso nyiaj 30% ua ntej thiab 70% ua ntej xa khoom xa tuaj.

Q4: Koj nyob qhov twg?Nws puas yooj yim tuaj xyuas koj?Peb nyob hauv Shanghai.Kev khiav tsheb yooj yim heev.

Q5: Koj tuaj yeem lav qhov zoo li cas?

1.Peb tau ua tiav cov txheej txheem ua haujlwm thiab cov txheej txheem thiab peb ua raws li lawv nruj heev.

2.Peb cov neeg ua haujlwm sib txawv yog lub luag haujlwm rau cov txheej txheem ua haujlwm sib txawv, lawv txoj haujlwm tau lees paub, thiab yuav ua haujlwm txhua lub sijhawm, yog li kev paub dhau los.

3. Cov khoom siv hluav taws xob pneumatic yog los ntawm lub ntiaj teb nto moo tuam txhab, xws li lub teb chaws Yelemees ^ Siemens, Japanese Panasonic thiab lwm yam.

4. Peb yuav ua qhov kev sim nruj heev tom qab lub tshuab ua tiav.

5.0ur tshuab tau ntawv pov thawj los ntawm SGS, ISO.

Q6: Koj puas tuaj yeem tsim lub tshuab raws li peb xav tau?Yog lawm.Peb tsis tsuas yog tuaj yeem kho lub tshuab raws li koj qhov kev kos duab techni cal, tab sis kuj tuaj yeem ua nws lub tshuab tshiab raws li koj xav tau.

Q7: Koj puas tuaj yeem muab kev pab cuam txawv teb chaws?

Yog lawm.Peb tuaj yeem xa engineer rau koj lub tuam txhab los teeb lub tshuab thiab cob qhia koj.